Руководство производителя оборудования для обработки рулонов: MD-850 - MD-2200 Технические характеристики и рамки выбора

Экспертное руководство по оборудованию для обработки рулонов: подробные технические характеристики серии MD (138,5 кВт-422,5 кВт), принципы работы, возможности работы с толщиной 0,3-12 мм, лучшие практики установки и оптимизация окупаемости инвестиций для автомобильной промышленности, HVAC и строительного сектора.

Selecting the right coil processing equipment manufacturer determines production efficiency, material yield, and long-term operational costs for metal fabrication facilities. Modern coil processing encompasses two fundamental technologies: slitting lines that longitudinally cut wide coils into multiple narrow strips, and cut-to-length (CTL) systems that transversely shear coiled stock into dimensionally precise flat sheets. Manufacturers processing stainless steel, carbon steel, aluminum, and galvanized materials require equipment delivering consistent width tolerances within ±0.15mm while maintaining processing speeds reaching 250 meters per minute.

Equipment selection extends beyond basic specifications to encompass material handling automation, precision control systems, energy efficiency, and manufacturer support infrastructure. Facilities processing 2,000-15,000 tons annually face capital equipment decisions with 15-20 year operational horizons, making comprehensive evaluation critical for competitive positioning and ROI achievement.

Technical Foundation: Slitting Versus CTL Processing

The distinction between slitting and CTL technologies addresses fundamentally different production requirements. Slitting lines excel when single master coils require conversion into multiple width configurations—a 1,250mm stainless steel coil might yield eight different strip widths ranging from 85mm to 220mm in a single processing run. This versatility serves fabricators supporting diverse downstream operations: stamping presses requiring specific blank widths, tube mill feeders with precise dimensional requirements, or edge-trimming applications generating secondary material streams.

CTL lines serve different production models. When fabrication processes demand flat sheets rather than coiled strips—think laser cutting tables, CNC punching equipment, or assembly operations requiring dimensionally stable blanks—CTL technology delivers material already leveled and cut to precise lengths. The leveling process eliminates coil set, the inherent curvature retained from coil packaging, which would otherwise require secondary straightening operations consuming both labor and floor space.

Material characteristics influence technology selection beyond geometric considerations. Aluminum alloys and copper, both exhibiting lower yield strengths than steel, often perform better through slitting processes that minimize material manipulation. Conversely, high-strength steels benefit from CTL leveling systems that plastically deform material beyond yield point, relieving internal stresses that could compromise flatness in finished components.

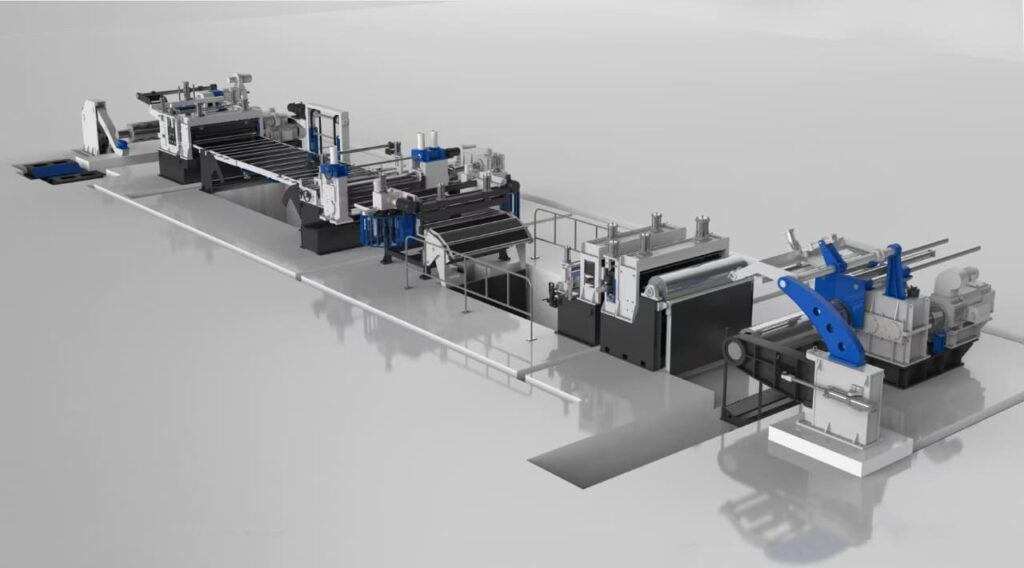

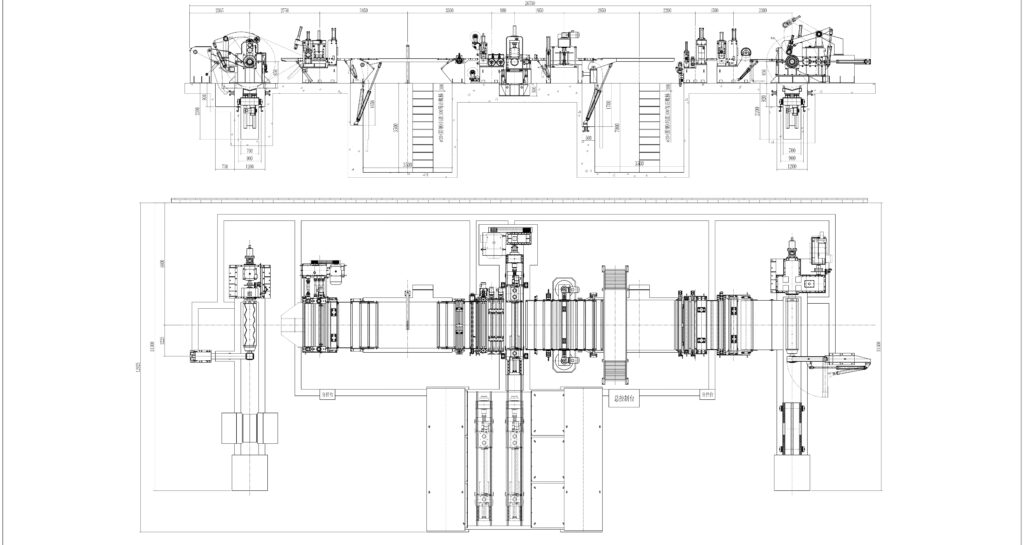

MD-Series Platform Architecture: Scalable Capacity Design

MaxdoMachine’s MD-series equipment reflects two decades of engineering evolution focused on modular scalability and application-specific optimization. Rather than forcing fabricators into arbitrary capacity categories, the platform progression addresses actual production scenarios encountered across automotive, HVAC, construction, and appliance manufacturing sectors.

MD-850: Compact Integration for Light-Gauge Production

The MD-850 platform targets facilities where floor space commands premium value and production centers on light-gauge materials. Processing coils from 300mm to 820mm width with 138.5kW installed power, this configuration serves HVAC ductwork fabricators, appliance component manufacturers, and specialty metal distributors handling frequent width changeovers. The compact footprint—approximately 18 meters line length versus 25-30 meters for larger platforms—enables installation in existing production facilities without major building modifications.

Material thickness capability spanning 0.3mm to 12mm across four distinct processing ranges provides surprising versatility. Electronics fabricators processing 0.3-0.8mm precision strips share equipment specifications with heavy-gauge contractors working 6-10mm structural materials, though actual production rarely combines such extremes on single installations. The 1-250 m/min variable speed range adapts to material characteristics: thin aluminum foils process at conservative 60-80 m/min speeds preventing edge tearing, while 1.5mm cold-rolled steel achieves full 200+ m/min throughput maximizing productivity.

Real-world applications demonstrate the platform’s range. A mid-Atlantic HVAC fabricator processes 3,500 tons annually of galvanized steel across twelve standard duct widths, achieving 96% material utilization through optimized nesting calculations. Their previous conventional equipment delivered 87% yield; the 9-point improvement generates $340,000 annual material savings on $1,150/ton galvanized substrate—an 18-month payback against equipment investment.

Explore detailed MD-850 specifications and compact design advantages for space-constrained facilities.

MD-1350: Mid-Range Workhorse for Automotive Applications

Width capacity expansion to 1,350mm positions this platform for automotive tier suppliers, appliance manufacturers, and precision strip producers serving stamping operations. The 318.5kW power system reflects enhanced coil handling requirements—30-ton master coils at 1,250mm width generate substantially higher uncoiler torque demands than equivalent tonnage on narrower formats.

Automotive applications drive many MD-1350 installations. Body panel production requires consistent strip width within ±0.10mm tolerances; progressive die operations cannot tolerate width variation that would generate misfeeds or dimensional errors in deep-drawn components. The servo-driven positioning system maintaining this accuracy operates across the full speed envelope, from 15 m/min during initial threading to 220 m/min production rates.

Knife configuration flexibility addresses material diversity. Processing stainless steel requires carbide-faced male knives operating against hardened female counterparts with 0.05-0.08mm overlap depth. Aluminum processing utilizes polished tool steel geometries with reduced overlap preventing edge galling. Copper demands specialized rake angles minimizing work hardening during shear separation. Equipment supporting multiple substrate types incorporates quick-change knife cassettes reducing changeover from 45 minutes to under 12 minutes—critical for service centers managing 8-12 coil changes per shift.

A Great Lakes automotive supplier processing 12,000 tons annually across eighteen product families reported 35% reduction in edge-related quality rejections following MD-1350 installation, attributing improvement to enhanced edge guidance systems and tension control architecture maintaining ±3% variation across full coil diameter range.

MD-1650 and MD-2200: Industrial Capacity for Wide-Format Requirements

These platforms address construction materials, shipbuilding components, and industrial equipment fabrication requiring processing beyond standard automotive widths. The MD-1650’s 1,650mm capacity serves structural panel manufacturers and roofing material producers, while the MD-2200’s 2,150mm width handles specialized applications including marine bulkhead materials and heavy construction components.

Power scaling to 422.5kW reflects the mechanical demands of processing 8-12mm thickness materials across wide formats. Shear cutting 10mm stainless steel at 1,800mm width generates cutting forces exceeding 450 kilonewtons—substantially higher than thin-gauge automotive materials. Enhanced structural rigidity, reinforced knife arbors, and upgraded drive trains maintain dimensional accuracy under these severe operating conditions.

The 500mm width differential between MD-1650 and MD-2200 platforms translates to significant throughput variations in wide-coil operations. Processing 1,950mm master coils on the MD-2200 enables full-width utilization with minimal edge trim; the same material on an MD-1650 requires 300mm total edge removal, reducing material yield from 97% to 84%—a substantial economic penalty on high-value specialty alloys.

Production facilities considering these industrial platforms typically process 8,000-25,000 tons annually with material values ranging $1,800-4,500 per ton for stainless and specialty alloys. The capital investment differential between platforms—approximately $180,000-240,000 favoring the smaller configuration—must be evaluated against material yield implications and throughput capacity. A shipyard processing 15,000 tons annually of 316L stainless at $3,200/ton calculated that the MD-2200’s 13-point yield advantage generated $6.2 million annual material savings, overwhelming the capital differential within six weeks of operation.

Review MD-2200 industrial platform capabilities for heavy-duty wide-format applications.

Comparative Platform Analysis

| Platform | Ширина Вместимость | Установленная мощность | Основные приложения | Диапазон толщины | Optimal Production Volume |

|---|---|---|---|---|---|

| MD-850 | 300-820 мм | 138,5 кВт | HVAC, appliances, light fabrication | 0,3-12 мм | 2,000-5,000 tons/year |

| MD-1350 | 300-1,350mm | 318,5 кВт | Automotive, precision strips, general fabrication | 0,3-12 мм | 5,000-12,000 tons/year |

| MD-1650 | 300-1,650mm | 422,5 кВт | Construction, wide-format steel, industrial components | 0,3-12 мм | 8,000-20,000 tons/year |

| MD-2200 | 300-2,150mm | 422,5 кВт | Shipbuilding, heavy fabrication, specialty wide materials | 0,3-12 мм | 12,000-30,000 tons/year |

Technical specifications verified from MaxdoMachine official sources

Platform selection depends on three primary factors: maximum coil width requirements, annual production volume, and material mix complexity. Facilities processing predominantly narrow formats (under 900mm) achieve optimal capital efficiency with MD-850 configurations, while those regularly handling 1,200-1,500mm coils require MD-1350 capacity. The industrial platforms serve specialized requirements where material widths or production volumes exceed standard configurations.

Mechanical Operating Principles: Precision Through Control

Understanding slitting mechanics clarifies the relationship between equipment design and output quality. The process appears deceptively simple—rotating circular knives shear material as web tension draws coil through the cutting station—yet achieving consistent ±0.10mm width tolerances at 200+ m/min demands sophisticated integration of mechanical systems and control architecture.

Tension Control: The Critical Foundation

Material tension management represents the single most influential parameter affecting slitting quality. Insufficient tension permits web flutter, lateral wandering, and inconsistent knife engagement producing ragged edges and width variation. Excessive tension stretches material beyond elastic limits, generating permanent elongation that alters finished strip dimensions and induces edge waviness in rewound coils.

Modern tension control employs closed-loop servo systems maintaining web stress within 2-3% of programmed setpoint across complete coil processing cycles. The challenge intensifies as coil diameter reduces during unwinding—maintaining constant web speed while coil radius decreases from 900mm to 300mm requires proportional braking torque increases following mathematical relationship (T = F \times r), where decreasing radius (r) demands increasing force (F) to maintain constant tension (T).

Load cells positioned on dancer roll assemblies provide real-time tension feedback. When measured values deviate from setpoint, the control system modulates uncoiler brake current and mainline drive speed within 0.05-second response windows, preventing the sustained deviations that would compromise edge quality. Advanced installations incorporate feed-forward algorithms predicting tension requirements based on coil diameter and material thickness, preemptively adjusting control parameters before deviations occur.

Material properties significantly influence optimal tension ranges. Aluminum processing typically operates at 40-60 kg/cm² web tension—substantially lower than the 80-120 kg/cm² range appropriate for cold-rolled steel. Stainless steel’s work-hardening characteristics require careful tension management preventing excessive work hardening that would alter material properties. Copper’s softness and surface sensitivity demands minimal tension with polished roller contact surfaces preventing marking.

Knife Geometry and Cutting Mechanics

Circular slitting knives operate through shear cutting mechanics fundamentally different from guillotine or punching processes. Male and female knife pairs create overlapping circular paths generating progressive shear fracture through material thickness. The overlap depth—typically 0.05-0.15mm depending on material thickness and type—determines cutting effectiveness and edge quality.

Insufficient overlap generates incomplete cuts, material tearing, and excessive burr formation. Excessive overlap crushes material rather than cleanly shearing it, creating work-hardened edges and accelerating knife wear. The optimal overlap varies with material: soft aluminum tolerates 0.05-0.08mm overlap, while high-strength steel requires 0.10-0.15mm penetration achieving complete fracture propagation.

Knife materials and surface treatments extend operational life while maintaining edge quality. Precision slitting applications utilize carbide-faced knives achieving 500-800 operational hours before requiring regrinding; standard tool steel configurations deliver 150-250 hour intervals. Surface coatings including titanium nitride and chromium nitride reduce friction and adhesive wear when processing aluminum or copper alloys prone to material transfer onto knife surfaces.

Edge preparation significantly impacts finished product quality. Knives require perpendicular cutting faces within 0.002mm runout tolerance—greater deviations generate helical cutting patterns producing wavy edges. Knife diameter matching ensures consistent overlap geometry across the knife set; diameter variations exceeding 0.05mm between male-female pairs create irregular cutting conditions generating quality variations across strip positions.

Investment Analysis and Economic Justification

Equipment acquisition requires comprehensive financial evaluation balancing capital investment against operational benefits and productivity improvements. The analysis extends beyond simple payback calculations to encompass strategic positioning, capacity utilization, and competitive advantage.

Material Yield Economics

Modern coil processing equipment achieves 95-97% material utilization compared to 82-87% realized with conventional systems or manual processing methods. This 10-15 point improvement generates substantial economic impact on operations processing significant tonnages of high-value materials.

Consider a fabrication facility processing 8,000 tons annually of 304 stainless steel averaging $3,200 per ton. Improving yield from 85% to 96% reduces material consumption by 11 percentage points—equivalent to 880 tons valued at $2.8 million. Equipment generating these savings justifies premium investment levels; installations costing $1.2-1.6 million achieve payback within 6-9 months purely from material savings, ignoring additional benefits from improved productivity, quality consistency, and labor reduction.

The calculation intensifies for specialty alloys. Titanium processors paying $15,000-25,000 per ton or nickel alloy fabricators purchasing at $8,000-12,000 per ton realize proportionally greater material savings. A medical device manufacturer processing 1,200 tons annually of titanium 6Al-4V at $18,500/ton reported that 12-point yield improvement generated $2.66 million annual material savings—a 4.2-month payback on $950,000 equipment investment.

Energy Efficiency Considerations

Servo-driven systems reduce electrical consumption 15-20% compared to conventional constant-speed motor control. The MD-1350’s 318.5kW nameplate capacity translates to approximately 220-240kW average demand during typical processing; conventional equipment of equivalent capacity averages 280-310kW consumption.

The differential—roughly 60kW continuous—operating 16 hours daily, 250 days annually, consumes 240,000 kWh additional electricity. At industrial rates averaging $0.09-0.12 per kWh, energy savings approach $22,000-29,000 annually. Over typical 15-year equipment service life, cumulative energy savings total $330,000-435,000—substantial though secondary to material yield economics.

Advanced installations incorporate regenerative drive systems recovering energy during deceleration phases. When decelerating recoiler motors or slowing mainline drives, conventional systems dissipate kinetic energy as heat through braking resistors. Regenerative configurations return this energy to facility electrical systems, improving overall efficiency an additional 8-12%. The incremental cost—approximately $35,000-50,000 for MD-1350 scale installations—achieves payback within 6-8 years on energy savings alone while providing ancillary benefits including reduced HVAC load from diminished heat dissipation.

Equipment Selection Decision Framework

Systematic selection methodology evaluates production requirements against equipment capabilities, matching specifications to actual operational needs rather than defaulting to maximum capacity assumptions.

Material Specification Documentation

Begin selection analysis documenting current and projected material characteristics:

Width Distribution Analysis: Survey 12-month production history identifying minimum, maximum, and mode width values processed. Calculate the percentage of production volume falling within specific width bands—this analysis often reveals surprising concentration where perceived diverse requirements actually cluster within narrower ranges than assumed. A fabricator convinced of requiring 1,650mm capacity may discover 87% of production processes within 1,200mm, making MD-1350 selection more economically rational.

Thickness Profiling: Categorize production volume by thickness range determining the proportion of light-gauge (0.3-3.0mm), medium-gauge (1.5-6mm), heavy-gauge (2-8mm), and ultra-heavy (4-12mm) processing. Equipment optimized for predominant thickness ranges delivers superior performance and economic efficiency compared to over-specified configurations addressing occasional extreme requirements potentially better handled through subcontracting.

Material Type Assessment: Document substrate distribution across carbon steel, stainless alloys, aluminum grades, copper, and specialty materials. Facilities processing predominantly single material types optimize equipment configurations for specific requirements; operations handling diverse materials require enhanced flexibility potentially justifying investment in more versatile platforms.

Production Volume and Growth Trajectory

Annual tonnage processed establishes baseline capacity requirements guiding platform selection. The MD-850 configuration optimally serves 2,000-5,000 ton annual production; exceeding this range risks inadequate capacity creating production bottlenecks. Conversely, specifying MD-1350 capability for 2,500-ton production results in under-utilization of capacity failing to achieve optimal return on incremental investment.

Growth projections require realistic assessment. Fabricators experiencing 8-12% annual growth logically anticipate doubling production within 6-8 years; equipment selection should accommodate this expansion without requiring premature replacement. However, optimistic growth assumptions frequently exceed realization—purchasing capacity for speculative future volume that fails to materialize wastes capital better deployed in current business optimization.

Market analysis informs growth predictions. Serving expanding sectors (electric vehicle components, renewable energy infrastructure, data center construction) justifies capacity planning for aggressive growth. Conversely, mature stable markets suggest conservative projections emphasizing current requirements over speculative expansion.

Quality and Precision Requirements

Dimensional tolerance specifications drive equipment selection as profoundly as capacity considerations. Applications requiring ±0.10mm width consistency demand premium equipment configurations; commercial-grade products tolerating ±0.30mm variations function adequately with standard configurations.

Downstream process requirements establish quality standards. Material feeding progressive stamping dies with close clearances requires tight dimensional control preventing die damage or production interruptions; generic fabrication applications tolerate broader specifications. Edge quality specifications similarly vary—welding applications demand burr-free edges, while painted assemblies tolerate minor edge imperfections.

Surface finish sensitivity influences material handling system design. Architectural stainless, pre-painted materials, and surface-critical aluminum require specialized roller coatings and web isolation preventing contact marking. Understanding actual requirements prevents over-specification while ensuring critical applications receive appropriate accommodation.

Operational Excellence Through Technical Support

Equipment performance depends equally on mechanical specification and manufacturer support infrastructure. Technical assistance quality, spare parts availability, and training resources significantly impact long-term operational success.

MaxdoMachine’s 20-year equipment manufacturing heritage provides application expertise across diverse fabrication sectors. The engineering team addresses installation planning, material handling optimization, and process parameter development supporting successful project implementation. This experience proves particularly valuable for fabricators entering new market segments or processing unfamiliar material specifications where proven processing parameters significantly compress development cycles.

Spare parts availability critically affects equipment uptime. Common wear components—blades, bearings, seals—require ready availability supporting rapid replacement minimizing production interruptions. MaxdoMachine maintains parts inventory supporting 24-48 hour delivery for routine components and provides cross-reference documentation identifying standard components sourced locally reducing dependency on extended international logistics.

Technical training equips operators and maintenance personnel with skills maximizing equipment capability. Comprehensive programs address operation procedures, quality troubleshooting, preventive maintenance execution, and safety protocols. Well-trained personnel identify developing problems before failures occur, optimize processing parameters for material characteristics, and execute maintenance preserving equipment accuracy throughout service life.

Заключение

Coil processing equipment selection represents strategic investment establishing operational capability and competitive positioning for 15-20 year time horizons. The decision process demands comprehensive evaluation of production requirements, material specifications, quality expectations, and organizational capabilities balanced against equipment specifications, manufacturer support infrastructure, and total cost of ownership.

MaxdoMachine’s MD-series platform architecture provides scalable solutions addressing diverse fabrication requirements from compact HVAC operations processing 2,000 tons annually through industrial heavy-fabrication facilities handling 25,000+ ton throughput. The engineering refinement reflecting two decades of manufacturing experience delivers reliability, precision, and operational efficiency supporting fabricators’ competitive success.

Organizations approaching equipment selection systematically—documenting requirements, evaluating alternatives objectively, and implementing professionally—achieve operational improvements extending beyond basic capacity expansion to encompass material yield optimization, quality enhancement, and labor productivity advancement. These comprehensive benefits transform equipment acquisition from necessary capital expenditure to strategic competitive advantage.

For detailed specifications, application engineering support, and custom configuration consultation, explore MaxdoMachine’s complete equipment portfolio and facility integration capabilities.