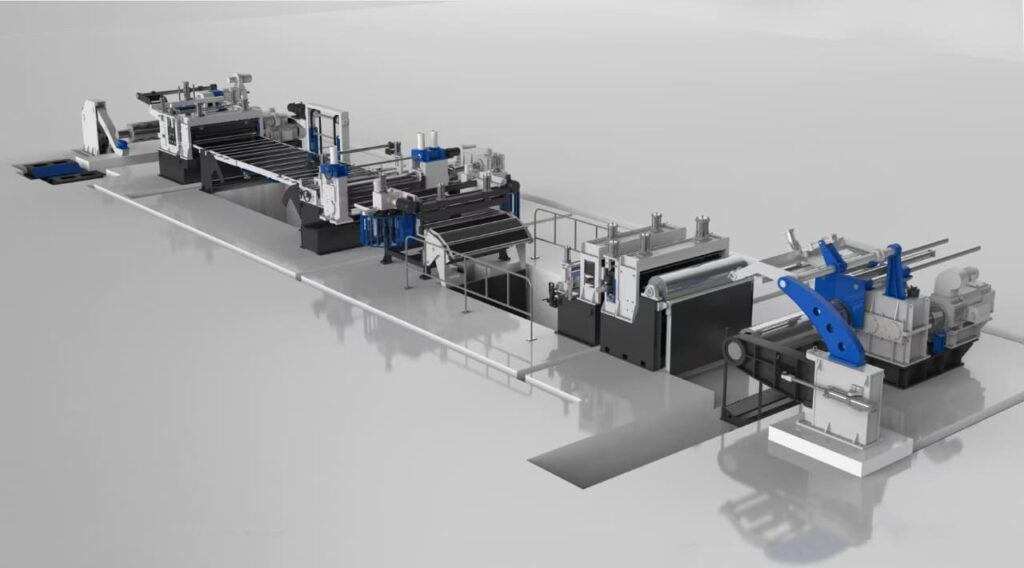

Multi-Blanking Line Material Flexibility: Complete Thickness & Strength Range Guide

Discover how multi-blanking systems process 0.3-12mm thickness ranges and 1400 MPa high-strength steel. Expert guide on multi-material capabilities for aluminum, stainless, and carbon steel with precision specifications.

TL;DR: Multi-blanking lines process materials from 0.3mm to 12mm thickness with tensile strengths up to 1400 MPa and yield strengths up to 1000 N/mm². Advanced systems like MaxDo’s MD series handle aluminum (0.3-3.0mm), mild steel (1.5-6mm), medium-gauge materials (2-8mm), and heavy-duty applications (4-12mm) with ±0.1mm precision across different material types including carbon steel, stainless steel, galvanized, and high-strength steel grades.

Understanding material flexibility is essential when evaluating comprehensive coil processing capabilities for your manufacturing operation, as different applications demand specific thickness and strength specifications. Multi-blanking lines deliver precision cut-to-length processing across diverse material portfolios, enabling steel service centers and fabricators to maximize equipment utilization.

The right equipment configuration balances thickness capacity, tensile strength handling, and width range to match your material mix. Production managers selecting multi-blanking systems must consider how thickness ranges align with material types—aluminum requires different processing parameters than ultra-high-strength automotive steel. This guide provides technical specifications for matching equipment capabilities to material requirements.

Thickness Range Capabilities by Material Type

Multi-blanking lines segment into three distinct thickness categories, each optimized for specific material applications.

Light-gauge processing handles 0.3-3.0mm materials including aluminum alloys, copper, thin stainless steel, and pre-painted steel. These applications demand precise tension control and specialized tooling to prevent surface damage on coated materials. The MD-850 and MD-1350 systems excel in this range, processing speeds up to 250 m/min while maintaining ±0.1mm dimensional accuracy.

Medium-gauge range spans 1.5-6mm for standard carbon steel, galvanized materials, and thicker stainless grades. This segment represents the highest-volume blanking applications across automotive, appliance, and construction sectors. Equipment must balance leveling force with material yield strength—780 MPa tensile strength materials exhibit 40-60% more elastic recovery than 350 MPa grades, requiring increased roll penetration depth.

Heavy-gauge capacity extends from 4-12mm for structural steel and high-strength applications. Processing thicker materials demands higher shearing force, robust leveling systems, and slower feed speeds to maintain edge quality. The MD-1350, MD-1650, and MD-2200 configurations handle this range with specialized roller assemblies and increased power capacity.

| MD Model | Width Range | Light-Gauge (0.3-3.0mm) | Medium-Gauge (1.5-6mm) | Heavy-Gauge (4-12mm) | Total Power |

|---|---|---|---|---|---|

| MD-850 | 300-820mm | ✓ Aluminum, Copper | ✓ Carbon Steel | ✓ Structural Steel | 138.5 kW |

| MD-1350 | 300-1350mm | ✓ All Light Materials | ✓ All Medium Materials | ✓ All Heavy Materials | 318.5 kW |

| MD-1650 | 300-1650mm | ✓ High-Speed Processing | ✓ Multi-Strip Capability | ✓ AHSS Compatible | 294.5 kW |

| MD-2200 | 300-2200mm | ✓ Maximum Width | ✓ Automotive Applications | ✓ Ultra-High Strength | Custom Config |

Tensile Strength and Yield Strength Specifications

Material strength directly impacts processing parameters, tooling selection, and achievable feed rates across multi-blanking operations.

Standard strength materials range from 245-490 MPa tensile strength for mild steel grades and aluminum alloys. These materials process at maximum line speeds (up to 250 m/min) with standard tooling configurations. Yield strengths typically fall between 140-340 MPa, requiring moderate leveling force to achieve flatness tolerances within ISO 2768 fine grade specifications.

Advanced high-strength steel (AHSS) begins at 440 MPa minimum tensile strength and extends to 980 MPa. Common automotive grades include dual-phase (DP), transformation-induced plasticity (TRIP), and complex-phase (CP) steels with yield strengths from 420-750 MPa. Processing AHSS demands increased shearing force—equipment must deliver 60-80% higher cutting pressure compared to mild steel while managing accelerated tool wear from abrasive resistance.

Ultra-high-strength steels (UHSS) exceed 980 MPa tensile strength, with martensitic grades reaching 1400-1500 MPa. Yield strengths range from 700-1000 N/mm² across these advanced metallurgies. Multi-blanking lines processing UHSS require specialized configurations: hardened shear blades, reinforced leveling rolls, and reduced processing speeds (typically 40-60% of mild steel rates). Material springback increases exponentially—1400 MPa materials exhibit 3-4 times more elastic recovery than 350 MPa grades, necessitating overbend compensation in leveling systems.

Temperature considerations also factor into AHSS processing. Materials above 780 MPa tensile strength generate significant heat during shearing, requiring blade cooling systems and thermal monitoring to prevent edge quality degradation. The MD series accommodates these demands through servo-controlled feed systems that adjust processing speed based on material strength input.

Multi-Material Processing Capabilities

Modern multi-blanking lines must handle diverse material portfolios to maximize ROI and operational flexibility.

Carbon steel grades represent the highest-volume blanking applications:

- Cold-rolled steel (CRS): 0.5-6mm thickness, 270-550 MPa tensile strength, ideal for automotive body panels and appliance components

- Hot-rolled pickled and oiled (HRPO): 2-12mm range, moderate strength (340-450 MPa), construction and structural applications

- Pre-painted steel: 0.4-2.5mm with polyester or PVDF coatings, requires specialized handling to prevent surface damage

Stainless steel processing demands material-specific configurations:

- 304 austenitic: Most common grade, 515 MPa minimum tensile strength, excellent formability but higher shearing force than carbon steel

- 316 austenitic: Corrosion-resistant applications, similar strength to 304 with elevated nickel content requiring blade maintenance protocols

- 430 ferritic: Lower cost alternative (450 MPa), magnetic properties, common in appliance manufacturing

Aluminum alloy compatibility spans multiple series classifications:

- 1000 series: Pure aluminum (99%+), low strength (70-130 MPa), soft tooling requirements

- 3000 series: Manganese alloys, moderate strength (110-280 MPa), excellent corrosion resistance

- 5000 series: Magnesium alloys, higher strength (190-350 MPa), marine and architectural applications

- 6000 series: Heat-treatable, 260-310 MPa, automotive structural components

Galvanized and coated materials require specialized handling protocols:

- G90 galvanized: Zinc coating thickness impacts edge quality, requires controlled shear clearance

- Galvannealed: Zinc-iron alloy coating, more brittle than pure zinc, prone to edge flaking without proper blade angles

- Aluminized Type 1/2: Aluminum-silicon coating, high heat resistance, automotive exhaust applications

High-strength steel grades for demanding applications:

- TRIP steels: 780-980 MPa, exceptional formability combined with strength

- Dual-phase (DP): 590-1180 MPa, continuous yielding behavior, automotive crash management

- Complex-phase (CP): 800-1000 MPa, excellent edge quality retention

- Martensitic steels: 1200-1500 MPa, limited formability, highest strength applications

Material switching protocols become critical for facilities processing multiple grades. Transitioning from aluminum to high-strength steel requires blade gap adjustment, tension recalibration, and leveling force modification—automated systems reduce changeover time from 45 minutes to under 10 minutes.

Width and Coil Weight Capacity Factors

Equipment width range and coil handling capacity directly constrain material flexibility across production schedules.

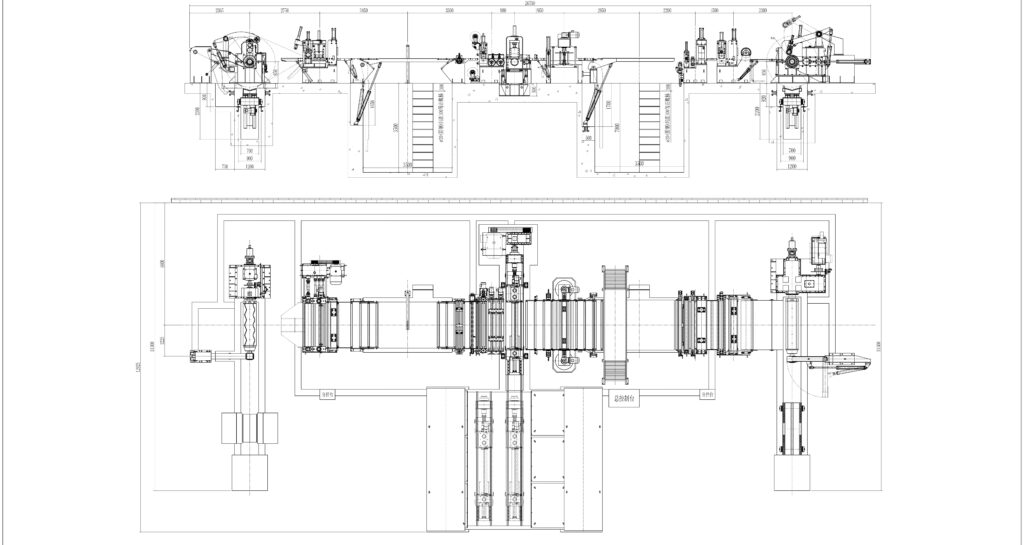

MaxDo’s MD series spans 300-2200mm width capacity, accommodating narrow-slit coils through full master coil processing. The MD-850 handles 300-820mm widths ideal for appliance panels and narrow construction materials. Mid-range MD-1350 (300-1350mm) serves automotive body components and HVAC applications. Heavy-duty MD-1650 and MD-2200 systems process full-width automotive steel and large-format architectural panels up to 2200mm.

Coil weight handling ranges from 10-40 tons depending on equipment configuration. Entry-level systems accommodate 10-ton coils suitable for light-gauge, narrow-width materials. Industrial configurations handle 25-35 ton master coils common in steel service center operations. Heavy-duty multi-blanking lines process coils exceeding 60,000 pounds (27+ tons) for maximum material utilization and reduced coil changes.

Strip width precision maintains ±0.1mm tolerance across the thickness range. This accuracy ensures consistent edge quality for downstream fabrication processes—stamping dies, press brakes, and robotic welding systems require dimensional repeatability within 0.15mm for reliable operation. Advanced servo-controlled edge trim systems on MD-1650 and MD-2200 models maintain precision even when processing materials with significant width variation in the master coil.

Multi-strip processing capability enables simultaneous blanking of 1-5 strips, dramatically increasing throughput for narrow-width applications. A 1350mm line can process five 250mm strips simultaneously, delivering 5x productivity compared to single-strip operation. However, multi-strip configurations demand precise slitting tolerances—width variation exceeding ±0.2mm across strips causes leveling inconsistencies that compromise flatness.

The relationship between material thickness, width, and processing speed follows inverse proportionality. A 1mm x 1000mm aluminum strip processes at 250 m/min, while 6mm x 1650mm high-strength steel reduces to 60-80 m/min to maintain shear quality and prevent excessive tool wear. Equipment selection must balance maximum capacity against typical material mix to optimize cycle times.

Equipment Selection for Material Requirements

Matching multi-blanking line specifications to your material portfolio maximizes equipment utilization and ROI.

MD-850 optimal applications:

- Light to medium-gauge processing: 0.3-6mm thickness range

- Width capacity: 300-820mm for appliance components, HVAC panels, narrow construction materials

- Material types: Aluminum, thin stainless steel, galvanized, mild carbon steel

- Speed optimization: Achieves 200+ m/min on light-gauge materials

- Power efficiency: 138.5kW total consumption suitable for facilities with standard electrical infrastructure

- Best for: Appliance manufacturers, HVAC fabricators, small-format automotive suppliers

MD-1350 versatile configuration:

- Full thickness range: 0.3-12mm handles light through heavy-gauge applications

- Mid-range width: 300-1350mm accommodates 80% of automotive and industrial applications

- Multi-material capability: Processes aluminum, stainless, AHSS, and ultra-high-strength steels

- Enhanced leveling: 318.5kW power capacity supports high-strength material processing

- Production flexibility: Optimal for service centers with diverse material portfolios

- Best for: Steel service centers, automotive tier suppliers, general metal fabrication

MD-1650/MD-2200 heavy-duty processing:

- Maximum width: 1650-2200mm for large-format automotive, construction, architectural applications

- High-strength specialization: Optimized for AHSS and UHSS processing with reinforced components

- Production volume: Heavy-duty construction supports high-volume (3+ shifts) operations

- Advanced automation: Integrated servo systems enable rapid material changeovers

- Custom configurations: Tailored leveling roll diameter, blade specifications, stacking systems

- Best for: Automotive OEM suppliers, heavy equipment manufacturers, high-volume service centers

Leveling system requirements scale with material yield strength. Materials under 350 MPa yield strength require 5-roll leveling configurations. AHSS grades (550-750 MPa yield) demand 7-9 roll systems with increased backup roll diameter to prevent deflection. Ultra-high-strength materials above 900 MPa necessitate 11-13 roll precision levelers with individual roll adjustment for managing complex stress patterns.

Servo control systems enable precision across varied material types. Traditional mechanical systems maintain fixed processing parameters, limiting material flexibility. Servo-driven MD series equipment adjusts feed speed, leveling force, and shear timing based on material input—operators select material grade from a digital library, and the system automatically configures optimal parameters. This automation reduces setup time by 75% when switching between aluminum and high-strength steel, directly improving equipment utilization rates.

Conclusion

Multi-blanking line material flexibility hinges on three critical specifications: thickness range (0.3-12mm), tensile strength capacity (up to 1400 MPa), and width handling (300-2200mm). Equipment selection must align with your material portfolio—light-gauge aluminum processors require different configurations than AHSS-focused automotive suppliers.

MaxDo’s MD series delivers comprehensive material compatibility through thickness-specific processing zones, servo-controlled automation, and precision leveling systems. The MD-850 optimizes light to medium-gauge operations, while MD-1350 provides maximum versatility across the complete thickness and strength spectrum.

For manufacturers processing diverse material portfolios, prioritize equipment with automated material changeover capabilities and multi-thickness range handling. Facilities focused on high-strength automotive applications should specify reinforced leveling systems and AHSS-compatible tooling.

Explore which materials MaxDo’s MD series slitting and shearing machines process for detailed material-specific processing parameters. Contact MaxDo’s engineering team to configure multi-blanking equipment matching your exact thickness, strength, and width requirements.