Best Cut to Length Line: Maxdomachine vs European CTL

Compare Maxdomachine CTL lines with premium European brands on ±0.10mm tolerance, 250 m/min speed, and 0.3-12mm range. Get a side-by-side TCO analysis now.

Procurement specialists finalizing vendor selection for cut-to-length (CTL) equipment face a decision that extends far beyond initial capital outlay. The performance gap between precision-engineered systems and adequate machinery manifests daily through tolerance drift, unplanned downtime, and rejected batches—costs that accumulate across 10-15 year equipment lifecycles. For light-gauge processing applications spanning 0.3mm to 12mm thickness, dimensional accuracy, feed system architecture, control intelligence, and post-sale support infrastructure determine whether a CTL line remains a competitive asset or becomes an operational constraint.

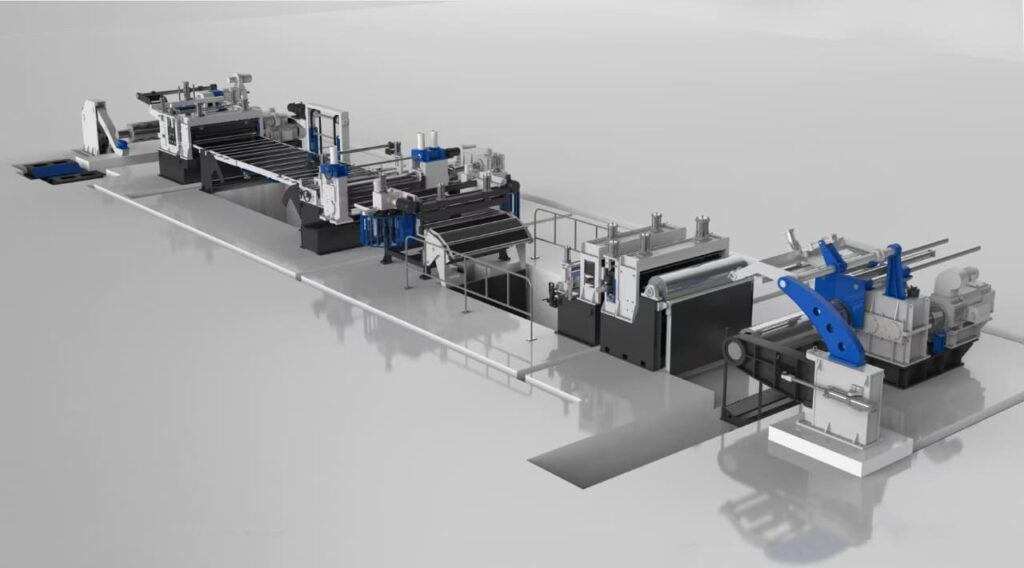

Maxdomachine’s MD series CTL platforms achieve ±0.10mm length accuracy through encoder-feedback servo measurement integrated with multi-roll leveling technology, maintaining these tolerances at processing speeds reaching 250 m/min across width capacities from 820mm to 2,150mm. This engineering foundation addresses the central challenge in light-gauge coil processing: eliminating coil-set memory and spring-back effects while preserving dimensional precision during sustained high-speed operation. Premium European manufacturers deliver established reliability and brand recognition, yet their hybrid mechanical-hydraulic architectures and specialized gauge-range platforms often introduce compromises that become evident under production scrutiny.

Precision Engineering: Where Tolerance Specifications Meet Production Reality

Dimensional Accuracy Under Industrial Conditions

Length tolerance directly determines downstream fabrication efficiency and scrap economics. Automotive body panel stamping, HVAC component production, and precision electronics enclosures demand sub-0.5mm cut-length accuracy that eliminates secondary operations and customer charge-backs. The distinction between ±0.10mm and ±0.25mm tolerance capability translates to 3-5% scrap rate differences on demanding applications, recovering equipment cost differentials within 18-24 months at moderate production volumes.

| Performance Metric | Maxdomachine MD Series | Premium European Manufacturer |

|---|---|---|

| Length tolerance (typical) | ±0.10mm standard / ±0.05mm advanced | ±0.127mm (±0.005″) to ±0.25mm |

| Width tolerance | ±0.05mm across material range | ±0.10mm to ±0.15mm |

| Flatness control | I-unit <3mm across 2m span | I-unit <4mm with 4-high/5-high leveler |

| Processing speed at full tolerance | Up to 250 m/min (MD-850, MD-1350, MD-1650) | 122-200 m/min typical, reducing with thickness |

| Material thickness range (single platform) | 0.3mm-12mm light to medium gauge | Segregated: <4mm (light) or 4-8mm (medium) |

Maxdomachine’s servo-driven measurement system employs rotary encoders that track material position continuously through closed-loop feedback, independent of surface texture, thickness variation, or coil-set irregularity. European manufacturers typically combine digital positioning with mechanical measurement wheels that contact the material surface. While achieving ±0.127mm capability on cold-rolled steel under ideal conditions, these contact-measurement approaches accumulate positional error during extended runs as wheel wear and surface contamination introduce measurement drift.

The difference becomes pronounced when processing materials exhibiting high spring-back characteristics. Advanced high-strength steel (AHSS) grades with 590-780 MPa yield strength and aluminum alloys retain elastic memory that conventional measurement systems interpret as dimensional variation rather than material behavior. Maxdomachine’s encoder feedback eliminates this ambiguity through position tracking that references the shear blade location directly, not material surface features.

Material Handling Across Gauge and Grade Ranges

Coil-set correction on light-gauge materials presents competing demands: apply sufficient plastic deformation to eliminate coil memory without inducing surface marking, work-hardening beyond specification, or edge distortion. Maxdomachine addresses this through multi-roll leveling units incorporating 9-15 working rolls with individually adjustable backing mechanisms. The MD-1350 configuration, processing widths from 300mm to 1,350mm, demonstrates this approach across 0.3mm to 12mm thickness ranges with 318.5kW power delivery maintaining torque consistency through varying material grades.

Premium European systems typically employ 4-high or 5-high leveler configurations optimized for specific thickness bands. Their light-gauge platforms (up to 3.5-4.0mm) achieve good flatness on cold-rolled mild steel but lack the roll count and backing adjustment range needed for high-strength grades or work-hardening alloys like austenitic stainless steel. Medium-gauge platforms (4-8mm) incorporate heavier leveling units but sacrifice maximum processing speed—often 60-80 m/min versus the 200-250 m/min capability Maxdomachine maintains across the full 0.3-12mm range.

This segregation approach creates operational gaps. A fabricator processing both 1.8mm automotive-grade HSLA steel and 5.5mm structural plate must either purchase separate light-gauge and medium-gauge lines or accept reduced throughput operating outside optimal specification windows. Maxdomachine’s unified platform architecture eliminates this compromise through power systems and leveling configurations designed for the full specification envelope.

Feed System Technology: Servo-Driven Control Versus Hybrid Mechanical Systems

Precision Through Closed-Loop Servo Architecture

Feed system design determines whether advertised tolerances remain consistent throughout eight-hour production shifts or degrade as operating conditions change. Maxdomachine employs high-torque servo motors with encoder feedback throughout material handling, measurement, and shearing functions. This architecture delivers positioning accuracy of ±0.02mm through proportional-integral-derivative (PID) control algorithms that compensate instantaneously for material stretch during feeding, cutting compression effects, and spring-back following shear.

The servo control advantage manifests across several performance dimensions:

Positional Precision: Closed-loop feedback eliminates accumulated error across batch runs. Where mechanical drive systems exhibit cumulative positional drift requiring mid-shift recalibration, servo systems maintain position accuracy independent of production duration.

Dynamic Response: Material property variations—coil diameter changes, thickness fluctuation, yield strength differences between heats—introduce feed resistance changes that mechanical systems cannot compensate for without operator intervention. Servo control adjusts torque and speed profiles in real-time, maintaining dimensional consistency across material transitions.

Energy Economics: Servo motors consume power proportional to work performed, idling at minimal draw during material threading, shear return, and stacking cycles. This contrasts with continuous hydraulic pump operation that consumes full power regardless of instantaneous demand. Field installations document 15-25% energy reduction versus hydraulic systems processing comparable throughput.

Motion Profiling: Programmable acceleration and deceleration curves prevent surface marking on soft metals and coated materials. Aluminum alloys and pre-painted steel require gentle material handling that abrupt mechanical start-stop cycles cannot provide.

Premium European Hybrid System Constraints

Leading European CTL manufacturers employ sophisticated combinations of servo measurement with hydraulic shearing and mechanical roll feeding. These hybrid architectures offer cost advantages through proven hydraulic shear technology but introduce variables that compromise precision under demanding conditions.

Grip feed systems—favored for thin-gauge materials below 2.0mm—advance material through intermittent gripping cycles that provide excellent positioning control but limit continuous processing speed to 122-150 m/min. The start-stop motion inherent to grip feeding restricts throughput and introduces material stress concentration at grip points, particularly problematic on brittle or work-hardening alloys.

Hydraulic shear systems deliver robust cutting force adequate for medium-gauge materials but exhibit timing variability as fluid temperature changes during production. Viscosity shifts with thermal cycling affect shear speed and position repeatability. Where Maxdomachine’s servo-driven shear maintains consistent blade velocity independent of operating temperature, hydraulic systems require compensation or mid-shift recalibration as fluid reaches operating temperature.

The maintenance burden differs substantially. Hydraulic systems demand regular fluid analysis, seal inspection and replacement, pump servicing, and contamination control—all introducing unplanned downtime risk. Servo systems eliminate hydraulic failure modes, reducing scheduled maintenance to bearing inspection, belt tension verification, and encoder cleaning.

Production Economics: Throughput and Material Yield

At 2,000 tons annual processing volume of light-gauge coils, the throughput difference between 120 m/min and 250 m/min processing speed represents 500-700 production hours annually under comparable uptime and job-mix assumptions. This capacity enables either production growth on existing shift schedules or labor cost reduction through shift consolidation, fundamentally changing facility economics.

Material utilization rates reveal cumulative precision effects. Maxdomachine systems achieve 97-98% material yield through optimized cutting pattern calculation and servo measurement accuracy. European systems typically deliver 92-95% utilization as tolerance stack-up and setup variation consume additional material. On 1,000 tons annual volume at typical steel pricing, this 3-5% difference represents $45,000-$75,000 in recovered material value—directly offsetting equipment cost differentials within initial payback periods.

Control Software: Production Intelligence Versus Traditional Automation

Maxdomachine Integrated Control Architecture

Modern CTL operation extends beyond mechanical precision into production optimization, quality documentation, and predictive maintenance. Maxdomachine’s PLC-servo integrated platform provides capabilities that transform operator interaction and management visibility:

Recipe-Based Material Management: The control system stores cutting patterns, leveling parameters, servo motion profiles, and shear timing for 500+ material specifications. Recipe selection automatically configures all machine functions, reducing changeover time from the 20-minute manual parameter entry typical of basic systems to under 7 minutes for complete material transitions. This database approach eliminates operator-dependent setup variation and enables rapid response to customer order changes.

Real-Time Quality Monitoring: Statistical process control trending tracks dimensional accuracy throughout production runs, alerting operators to tolerance drift before scrap occurs. Automatic adjustment algorithms compensate for predictable variations—coil diameter reduction, material temperature changes, blade wear progression—without manual intervention.

Production Data Integration: For fabricators pursuing automotive industry certification or ISO 9001 traceability requirements, the control system logs every cut length, timestamp, operator ID, and material batch code with export capability to enterprise resource planning (ERP) and manufacturing execution systems (MES). This documentation infrastructure supports customer audits and claim resolution without manual record reconstruction.

Predictive Maintenance Infrastructure: Component runtime tracking provides service interval alerts preventing unexpected failures. Vibration monitoring on critical drive systems identifies bearing degradation before quality impact occurs. Cutting blade wear analysis recommends optimal replacement timing based on actual cut count and material grades processed, minimizing both premature replacement waste and scrap from worn tooling.

Remote Diagnostic Capability: When technical issues arise, secure remote access enables Maxdomachine support engineers to review operating parameters, alarm history, and servo performance data without site travel. This infrastructure resolves an estimated 70% of technical inquiries through remote guidance, dramatically reducing downtime duration.

Premium European Control Capabilities

European manufacturers provide robust PLC control with digital positioning systems delivering proven performance for standard production environments. Their packages include CNC-controlled positioning, recipe storage for common specifications (typically 50-100 programs), and comprehensive safety interlocking meeting CE and OSHA compliance standards.

The distinction lies in adaptive capability and enterprise integration. Standard European systems require manual parameter entry and verification for material changeovers rather than automated recipe selection. Quality monitoring typically depends on periodic sample measurement instead of continuous statistical trending. Production data logging, when provided, often uses proprietary formats incompatible with customer ERP systems, requiring manual transcription for documentation purposes.

For OEMs running diverse material specifications or pursuing automotive industry quality certification, these control system differences create operational friction that accumulates across thousands of production hours annually.

Customization Philosophy: Application-Specific Engineering Versus Standard Platforms

Maxdomachine Configuration Flexibility

Light-gauge processing encompasses applications from 0.3mm stainless steel foil for electronics to 12mm high-strength plate for structural components—materials exhibiting vastly different mechanical properties, surface finish requirements, and dimensional tolerances. Maxdomachine addresses this spectrum through four base platforms with extensive customization capability:

MD-850 Compact Configuration (Cutlength 850):

- Width capacity: 20mm to 820mm

- Thickness range: 0.3mm-12mm across multiple hardness grades

- Processing speed: 1-250 m/min with variable speed servo control

- Total power: 138.5kW for consistent performance

- Coil weight: 10-35 tons customizable

- Applications: Precision strips, specialty alloys, HVAC components, appliance panels

- Customization options: Servo edge-guide systems, precision stacking with automatic sheet separation, integrated material identification

MD-1350 Mid-Range Platform (CT-1350):

- Width capacity: 300mm to 1,350mm

- Standard specifications: 0.3mm-12mm thickness, speeds to 250 m/min

- Total power: 318.5kW optimized for energy efficiency with servo drive systems

- Coil capacity: 10-35 tons standard

- Processing speed: 1-250 m/min maintained across specification range

- Customization: Integrated punching stations, automatic width adjustment, coil car loading systems, vision-guided edge detection

- Target production: 1,500-3,000 tons annually across diverse material grades and customer specifications

MD-1650 High-Capacity System (CT-1650):

- Width range: 300-1,650mm

- Thickness capability: 0.3mm-12mm light to medium gauge

- Power configuration: 422.5kW servo-driven architecture

- Coil capacity: 10-35 tons expandable to 50 tons with dual-drive uncoiler

- Processing speed: 1-250 m/min across full width and thickness envelope

- Applications: Structural panel manufacturing, roofing material production, wide-format blanking

- Advanced options: Automatic thickness measurement, integrated flatness verification, temperature-compensated servo measurement for AHSS grades

MD-2200 Maximum-Width Platform:

- Width capacity: 300-2,150mm

- Complete light and medium-gauge thickness range support

- Customizable power systems for high-volume continuous operation

- Specialized configurations for shipbuilding, construction equipment, large-appliance manufacturing

Application-Specific Engineering: AHSS Processing Example

A Great Lakes region automotive Tier 1 supplier required processing advanced high-strength steel with 780 MPa yield strength in 1.2mm to 2.5mm thickness, maintaining ±0.08mm length tolerance for body-in-white structural components. Standard CTL equipment achieved ±0.15mm capability on this material, insufficient for the customer’s stamping die clearances and dimensional stack-up requirements.

The custom MD-1350 configuration incorporated enhanced leveling with 13 working rolls providing controlled plastic deformation optimized for AHSS spring-back characteristics. Temperature-compensated servo measurement accounted for thermal expansion effects in high-strength grades that conventional systems interpret as dimensional variation. Carbide-faced shear blades extended replacement intervals to 500,000 cuts versus 200,000 cuts for standard tooling on this abrasive material grade. Integrated flatness measurement verified I-unit specification compliance before automatic stacking, providing quality documentation meeting automotive supplier requirements.

This engineering approach addresses specific metallurgical and dimensional challenges rather than requiring process adaptation to standard equipment limitations. The result: 98% first-pass yield on a material grade that typically produces 92-94% yield on conventional CTL systems.

Premium European Platform Standardization

European manufacturers offer distinct product lines segregated by gauge range: light-gauge systems (up to 3.5-4.0mm), medium-gauge platforms (4-8mm), and heavy-gauge configurations (up to 25mm). Their light-gauge lines typically specify:

- Maximum width: 1,800-2,000mm

- Maximum thickness: 3.5-4.0mm

- Maximum coil weight: 35-40 tons

- Processing speed: 200 m/min maximum on thinnest gauges, reducing to 60-80 m/min approaching maximum thickness

- Shearing systems: Mechanical stop/start or rotary shear configurations

This segregation optimizes each platform for its specific gauge band but creates capability gaps. Operations processing both 1.5mm and 6.0mm materials must either purchase multiple dedicated lines or accept reduced performance operating outside optimal specification windows. The first approach doubles capital investment and floor space requirements; the second sacrifices throughput and precision.

Maxdomachine’s unified platform architecture eliminates this compromise through power systems, leveling configurations, and servo control designed for the complete 0.3-12mm specification envelope on a single production line.

Warranty and Support: Protecting Operational Continuity

Maxdomachine Support Infrastructure

Capital equipment decisions extend into decade-long operational relationships where technical support responsiveness directly determines production continuity. Maxdomachine’s support structure reflects this reality:

Warranty Coverage:

- 24-month comprehensive warranty on mechanical assemblies, electrical systems, servo drives, and control software

- Five-year structural frame warranty covering welded construction and base assemblies

- Lifetime technical support access for original equipment purchasers regardless of ownership transfers

- First-year consumables package including initial shear blade sets, leveling roll assemblies, and guide components

Technical Response Infrastructure:

- Regional service centers providing native-language support with local industrial expertise

- 24-hour emergency response via remote diagnostics resolving approximately 70% of technical issues without site visits

- Preventive maintenance training during installation commissioning, enabling customer teams to perform routine service independently

- Annual technical audits identifying optimization opportunities, component life projections, and recommended upgrades

Spare Parts Strategy:

- Critical component inventory at regional distribution centers enabling 48-hour delivery for urgent requirements

- Complete bill-of-materials documentation with OEM part numbers and aftermarket equivalent specifications supporting competitive sourcing

- 10-year minimum parts availability guarantee for discontinued models protecting long-term asset value

- Technical drawings and assembly procedures supporting customer maintenance capabilities and reducing dependency on vendor technicians

Service Model Economics: Downtime Cost Reality

The MD-1350 installed at a Cincinnati fabricator in 2018 illustrates support infrastructure value. During 2023 third-shift operation, a servo motor encoder failed, causing dimensional drift detected by the quality monitoring system. The operator contacted emergency support at 2:30 AM; remote diagnostics identified encoder failure within 20 minutes. Expedited parts shipment arrived at 9:00 AM the following morning. Maxdomachine technical support guided the customer maintenance team through encoder replacement via video conference during first shift. Total downtime: 14 hours from fault detection to full production resumption.

Comparable situations with European manufacturers requiring factory technician deployment typically extend 3-5 days accounting for technician scheduling, international travel logistics, and time zone coordination. At $15,000-25,000 per day lost production value for a medium-capacity CTL line, downtime duration differences exceed monthly equipment payments.

Premium European Support Standards

European manufacturers provide 12-24 month component warranty with extended structural coverage. Their support infrastructure includes factory-based technical teams with business-hours availability, authorized service networks in major industrial regions, factory training programs for customer maintenance personnel, and OEM parts supply through distributor networks.

The primary distinction lies in geographic response capability. European manufacturers maintain excellent factory support but regional presence varies significantly by market. For North American and Asian installations, emergency response may require 24-72 hours for parts procurement and technician deployment. Operations running multiple shifts or supporting just-in-time customer schedules face cascading supply chain impacts from extended downtime that can dwarf equipment cost differentials.

Lead Time Realities: Project Schedule Confidence

Maxdomachine Delivery Framework

Production scheduling transparency prevents facility expansion delays that disrupt customer commitments and capital budgets. Maxdomachine provides structured timelines with milestone visibility:

Standard Configuration Lead Times:

- MD-850: 12-14 weeks from order confirmation to factory acceptance testing

- MD-1350: 14-16 weeks including commissioning documentation

- MD-1650/MD-2200: 16-20 weeks for high-capacity systems with custom configurations

- Custom specifications: Additional 2-4 weeks for engineering validation and specialized component procurement

Project Communication Protocol:

- Weekly production updates with photography documentation of assembly progress and quality inspection checkpoints

- Factory acceptance testing scheduled with customer attendance opportunity for hands-on operator familiarization

- Detailed shipping and logistics coordination beginning 4 weeks prior to delivery, including customs documentation for international installations

- On-site installation support with commissioning engineering team deployment (5-7 days typical duration)

Maxdomachine’s modular assembly approach enables parallel production of subsystems—leveling units, control cabinets, base frames, and material handling components proceed simultaneously with final integration during the concluding 3 weeks before testing. This methodology reduces critical path dependencies that create schedule delays when individual components encounter procurement issues.

The company maintains strategic inventory for long-lead components including precision servo motors, encoder systems, and specialized bearing assemblies. This buffer absorbs supply chain disruptions without impacting committed customer delivery dates—particularly valuable during periods of global component scarcity.

Premium European Delivery Considerations

European manufacturers typically quote 16-26 week lead times for standard configurations, extending to 28-36 weeks for custom specifications. Delivery schedules reflect queue-based production with limited visibility to actual manufacturing start dates, component sourcing from European suppliers with extended procurement cycles, sea freight transportation adding 4-6 weeks for North American and Asian deliveries, and installation requiring factory technician deployment for 2-3 week commissioning periods.

For facility expansions coordinating multiple equipment installations, delivery schedule uncertainty forces either early ordering with extended capital commitment or construction completion risk without operational equipment. The financial impact of 2-3 month schedule variability includes carrying costs on capital, opportunity cost of delayed production startup, and potential customer contract penalties for late delivery.

Total Cost of Ownership: The 10-Year Economic Framework

Investment Analysis Beyond Acquisition Price

Premium European manufacturers typically command 20-30% higher acquisition costs than Maxdomachine for comparable capacity specifications, justified by established brand recognition and perceived quality advantages. Total cost of ownership analysis across realistic 10-15 year equipment lifecycles reveals different economics:

Precision Economics: For operations processing 2,000 tons annually of automotive-grade HSLA steel or precision-tolerance stainless, the difference between ±0.10mm and ±0.20mm capability equals 3-5% scrap rate reduction. At $1,200/ton material cost, this represents $72,000-120,000 annual recovered value, recovering equipment cost differentials within 18-24 months.

Throughput Impact: Maxdomachine’s 250 m/min maximum speed versus European manufacturers’ 122-200 m/min capability translates to 25-50% higher hourly throughput on light-gauge materials under comparable operating conditions. This enables single-shift operation matching two-shift requirements on slower equipment, fundamentally altering labor economics and facility overhead allocation.

Energy Economics: Servo technology’s 15-25% energy advantage provides ongoing operational savings throughout equipment life. On a typical MD-1350 installation consuming 318.5kW during operation, this efficiency gain accumulates to $25,000-40,000 over 10 years at industrial electricity rates.

Maintenance Cost Structure: Fully servo-driven systems eliminate hydraulic fluid purchase, seal replacement schedules, and pump servicing requirements. Field data indicates 20-30% lower annual maintenance budgets compared to hybrid hydraulic-mechanical systems processing comparable tonnage.

Downtime Risk Economics: Extended warranty coverage and regional technical support infrastructure minimize production interruption costs. The value difference between 14-hour and 72-hour emergency response on critical failures exceeds $50,000-75,000 per incident for medium-capacity installations—potentially occurring multiple times across equipment lifecycle.

Decision Framework: Matching Capability to Production Requirements

The comparison between Maxdomachine and premium European manufacturers centers on aligning technical capabilities with actual production requirements, material specifications, and quality standards rather than brand perception or initial price considerations. For buyers shortlisting the best cut-to-length line for light-gauge production, four capability dimensions define the real value proposition:

High-Mix, High-Precision Operations

Fabricators processing diverse material specifications—varying thickness, width, grade, and surface finish requirements—demand equipment that maintains consistent performance across the complete specification envelope without productivity-killing changeover delays. For OEMs working under ISO 2768 general tolerance standards (medium tolerance class: ±0.10mm for 30-120mm dimensions) and ISO 9445 flatness requirements for stainless steel sheet and strip, maintaining ±0.10mm cut-length accuracy often determines first-pass yield versus rework cycles.

Maxdomachine’s ±0.10mm standard tolerance, full servo control architecture, and 0.3-12mm thickness range on unified platforms provides significantly greater flexibility than most single-purpose light-gauge or medium-gauge lines segregating these capabilities across separate equipment. Recipe-based material management reducing changeover to under 7 minutes enables economical small-batch production and rapid response to customer order changes.

Maximum Throughput and Labor Economics

Processing speed capability directly determines production capacity and shift requirements. At 2,000 tons annual volume of light-gauge coils, the difference between 120 m/min and 250 m/min processing represents 500-700 freed production hours annually under comparable uptime and job-mix assumptions. This capacity enables either production growth on existing shift schedules or shift consolidation reducing labor costs and facility overhead burden.

For operations approaching capacity constraints, Maxdomachine’s sustained 250 m/min capability across the full 0.3-12mm thickness range offers expansion headroom without facility enlargement or additional equipment investment.

Advanced Materials Processing

High-strength steels, aluminum alloys, and specialty metals demand adaptive control and multi-roll leveling that Maxdomachine provides as standard features rather than expensive upgrades. AHSS grades with 590-980 MPa yield strength, duplex stainless steels exhibiting work-hardening characteristics, and aluminum alloys with high spring-back memory defeat conventional 4-high/5-high leveling systems and contact-measurement architectures.

Operations processing these demanding materials benefit from servo measurement eliminating contact-wheel error accumulation, multi-roll leveling providing controlled plastic deformation without surface marking, and programmable motion profiles preventing material damage during handling.

Long-Term Support Confidence

Regional service infrastructure with 24-hour emergency response and lifetime technical support access protects operational continuity more effectively than factory-based support requiring international technician deployment. For operations running multiple shifts, supporting just-in-time customer delivery schedules, or located in secondary markets with limited local industrial service infrastructure, response time differences between 14 hours and 3-5 days directly determine customer retention and production schedule reliability.

When procurement specialists evaluate these factors against specific production requirements, material portfolios, quality standards, and total cost of ownership projections, the decision framework shifts from comparative shopping to strategic capability investment. The initial price differential between equipment options becomes one variable within a comprehensive economic model incorporating precision economics, throughput capacity, energy efficiency, maintenance burden, and downtime risk across realistic 10-15 year ownership horizons.

Request your detailed, side-by-side comparison analyzing total cost of ownership for your specific material specifications, production volume requirements, and quality standards. Maxdomachine’s application engineering team will conduct technical analysis demonstrating how precision engineering, servo-driven control, and comprehensive support infrastructure translate into measurable competitive advantages for your operations. Contact us today to discuss your light-gauge processing requirements and receive a customized equipment proposal addressing your unique production challenges.