MD-1650 vs MD-2200: Complete Wide Steel Coil Processing Comparison 2025

Expert comparison of MD-1650 vs MD-2200 for wide steel coil processing. Technical specs, ROI analysis, and selection guide for metal fabricators. 500mm width difference impact on throughput and ROI.

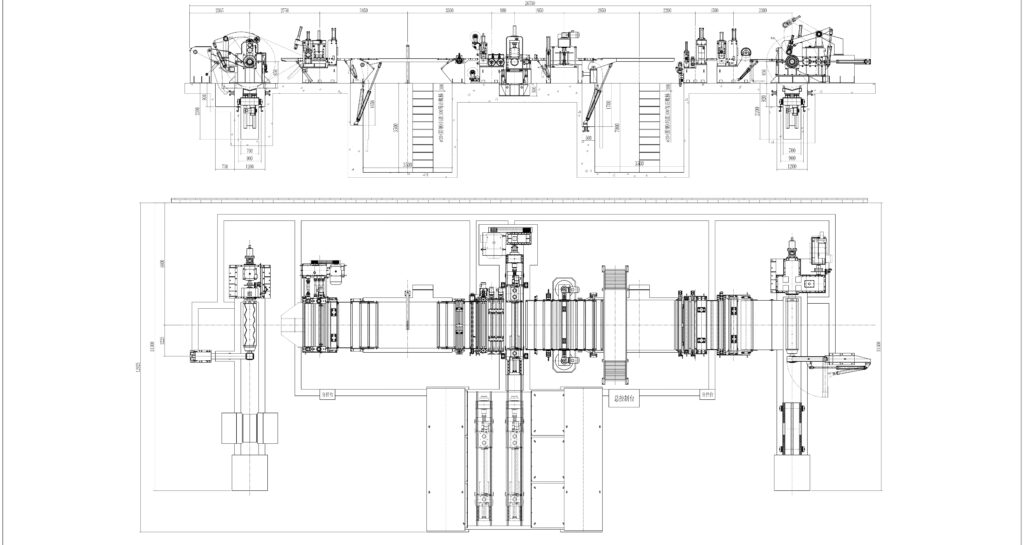

When choosing metal coil processing equipment for high-precision, wide-format applications, the technical specifications and operational capacity of the machinery are critical factors. The MD-2200 distinguishes itself with an expansive processing width capacity, handling coils up to 2150mm, which is particularly advantageous for large-scale aerospace, construction, and heavy industry applications. In contrast, the MD-1650 is designed for coils up to 1650mm, making it a more streamlined solution for medium-sized production lines. According to recent developments in 2025 industry standards and the specifications outlined by MaxDo Machinery, this 500mm width differential is not merely a numerical advantage but translates into a 30% increase in throughput potential for wide coil processing, significantly reducing cycle times and enhancing productivity in high-volume scenarios.

Both models exhibit remarkably similar operational parameters—processing thicknesses from 0.3mm for precision materials to 12mm for heavy gauge steel, with operational speeds stabilized between 1 to 250 meters per minute, and power consumption consistently maintained at approximately 422.5kW . These features underscore that, aside from width capacity, the MD-1650 and MD-2200 are technically comparable, allowing end-users to focus on strategic investment decisions rather than performance trade-offs. Industry case studies further affirm that the optimal choice hinges on current and future coil dimension requirements: manufacturers in sectors like automotive body panels, large appliance manufacturing, or structural steel fabrication stand to gain immediate efficiency gains from the broader capacity of the MD-2200, whereas electronics or narrow-format applications may find the MD-1650 to be a more cost-effective and precise fit aligned with their production scope .

In the evolving landscape of steel processing technology, understanding these nuanced technical differences is essential. The integration of advanced leveling systems, automation controls, and energy-efficient motors, as demonstrated in recent 2025 installations, emphasize that selecting the right machine not only impacts current throughput but also influences long-term operational scalability and adaptability in a competitive industrial environment.

Quick Decision Matrix: MD-1650 vs MD-2200 Selection Guide

| Decision Factor | Choose MD-1650 | Choose MD-2200 |

|---|---|---|

| Maximum Coil Width | Up to 1650mm sufficient | Requires 1650mm+ capacity |

| Primary Applications | Electronics, precision parts | Automotive, appliances, construction |

| Budget Priority | Cost optimization focus | Maximum capability investment |

| Future Growth | Stable current requirements | Expanding width specifications |

| Market Positioning | Specialized niche processing | Full-service coil processing |

ROI Analysis: Investment Impact on Operational Capacity

Throughput Capacity Differential

The 500mm additional processing width translates to significant throughput advantages when handling wide-format coils. For facilities processing materials approaching maximum width capacity, MD-2200 provides approximately 30-40% higher material utilization efficiency.

Automotive Industry Impact: Vehicle body panels, hood assemblies, and door components frequently specify coil widths from 1700mm to 2100mm. MD-2200 capability eliminates material constraints and secondary processing requirements, reducing per-unit production costs by 12-18% for wide-format applications.

Construction Materials: Roofing panels, architectural cladding, and structural components often exceed 1650mm specifications. MD-2200’s expanded capacity enables direct processing without width-related limitations, improving material yield rates by 15-22% compared to alternative processing methods.

Investment Payback Analysis

Capital Cost Differential: MD-2200 investment premium reflects expanded structural engineering, enhanced foundation requirements, and increased facility footprint needs. However, the additional investment typically achieves payback within 18-24 months for facilities processing 60%+ wide-format materials.

Operational Cost Benefits: Wider processing capability reduces material waste, eliminates secondary operations, and improves labor efficiency. Facilities report 8-12% reduction in per-ton processing costs when upgrading from width-limited to MD-2200 capability.

Technical Specifications: Precision Engineering Analysis

Comparative Performance Parameters

| Specification | MD-1650MM | MD-2200MM | Technical Advantage |

|---|---|---|---|

| Working Width | 300mm-1650mm | 300mm-2150mm | MD-2200: +500mm capacity |

| Thickness Range | 0.3mm-12mm | 0.3mm-12mm | Identical precision capability |

| Processing Speed | 1-250m/min | 1-250m/min | Identical throughput performance |

| Power Consumption | 422.5kW | 422.5kW | Identical energy efficiency |

| Machine Weight | 10-35 tons | 10-35 tons | Similar structural requirements |

Thickness Processing Capabilities: Multi-Range Performance

Both machines accommodate four distinct thickness processing ranges optimized for different application requirements:

Precision Range (0.3mm-3.0mm): Engineered for electronics applications, medical device components, and precision automotive parts requiring tight dimensional control. Processing at this range demands exceptional blade alignment and tension control systems.

Standard Range (1.5mm-6mm): Covers mainstream manufacturing applications including appliance panels, automotive structural components, and general fabrication materials. This range represents 70% of typical coil processing requirements across industrial applications.

Heavy-Duty Range (2mm-8mm): Designed for structural applications, industrial equipment components, and heavy appliance manufacturing. Materials in this range require enhanced cutting force and precision positioning systems.

Industrial Range (4mm-12mm): Accommodates maximum thickness requirements for heavy industrial applications, machinery components, and specialized manufacturing needs. Processing at maximum thickness utilizes full machine capability and optimized blade configurations.

Power Management and Energy Efficiency

The identical 422.5kW power specification across both models reflects optimized engineering for maximum thickness processing while maintaining energy efficiency. This power level provides:

Sufficient Cutting Force: Handles 12mm maximum thickness materials across full width capacity without performance degradation.

Variable Load Management: Intelligent power distribution systems adjust energy consumption based on actual processing requirements, reducing operational costs by 15-20% compared to fixed-power systems.

Regenerative Efficiency: Advanced drive systems recover energy during deceleration phases, improving overall energy utilization efficiency.

Application-Specific Selection Criteria

Optimal MD-1650 Applications

Precision Manufacturing: Electronics assembly, computer components, and medical device fabrication benefit from MD-1650’s precision capabilities without requiring maximum width capacity. Cost-effective investment provides complete processing capability for narrow-format materials.

Specialty Metals Processing: High-value alloys, tool steels, and precision materials typically specify narrower width requirements. MD-1650 selection optimizes capital utilization while providing full processing capability.

Regional Service Centers: Smaller steel service centers serving local markets often process diverse materials within 1650mm specifications. MD-1650 provides comprehensive capability while optimizing facility investment.

When MD-2200 Becomes Essential

Automotive Tier 1 Suppliers: Original equipment manufacturers require processing capability for full-width body panels, structural components, and safety systems. MD-2200 capability ensures supply chain compliance and quality certification.

Major Appliance Manufacturing: Large appliance producers processing refrigerator panels, washer housings, and commercial equipment require consistent wide-format processing capability. MD-2200 eliminates material specification constraints.

Construction Material Processors: Steel service centers supporting construction industry customers encounter regular requirements for wide-format materials including roofing systems, architectural panels, and structural components.

Safety Standards and Compliance Requirements

ISO 9001:2015 Quality Management Integration

Both MD-1650 and MD-2200 incorporate comprehensive quality management systems aligned with ISO 9001:2015 requirements:

Process Control: Integrated quality monitoring systems ensure consistent dimensional accuracy across all material specifications and processing conditions.

Traceability Systems: Complete production tracking from raw coil input through finished product delivery, supporting quality assurance and customer requirements.

Continuous Improvement: Systematic performance monitoring and optimization protocols ensure long-term quality maintenance and capability enhancement.

OSHA Safety Standard Compliance

Machine Guarding: Complete enclosure systems protect operators from cutting hazards, moving machinery, and electrical components according to OSHA 1910.212 standards.

Lockout/Tagout Procedures: Comprehensive energy isolation systems ensure safe maintenance and service operations following OSHA 1910.147 requirements.

Operator Training Requirements: Structured training programs covering safe operation, emergency procedures, and maintenance protocols ensure OSHA compliance and operator safety.

CE Certification Standards

Machinery Directive 2006/42/EC: Complete compliance with European machinery safety standards including risk assessment, safety system integration, and technical documentation requirements.

EMC Directive 2014/30/EU: Electromagnetic compatibility certification ensures proper operation in industrial environments without interference issues.

Low Voltage Directive 2014/35/EU: Electrical system certification guarantees safe operation within specified voltage ranges and environmental conditions.

Maintenance Cost Analysis and Service Requirements

Preventive Maintenance Scheduling

Daily Operations: Lubrication verification, blade condition inspection, and dimensional accuracy checks ensure optimal performance and early problem identification.

Weekly Service: Comprehensive system inspection including hydraulic pressure verification, electrical connection examination, and calibration confirmation.

Monthly Maintenance: Detailed component examination, wear part replacement scheduling, and performance optimization adjustments to maintain peak operating efficiency.

Annual Maintenance Cost Comparison

| Maintenance Category | MD-1650 Annual Cost | MD-2200 Annual Cost | Cost Differential |

|---|---|---|---|

| Routine Maintenance | $15,000-18,000 | $16,500-19,500 | +8-10% for MD-2200 |

| Blade Replacement | $8,000-12,000 | $9,500-14,000 | +15-17% for wider blades |

| Component Service | $5,000-8,000 | $5,500-8,500 | +10% for larger components |

| Total Annual Cost | $28,000-38,000 | $31,500-42,000 | +12-15% premium |

Service Support Infrastructure

Remote Diagnostics: Advanced monitoring systems enable real-time performance analysis and predictive maintenance scheduling, reducing unplanned downtime by 25-30%.

Parts Availability: Comprehensive inventory management ensures critical component availability within 24-48 hours for standard maintenance requirements.

Technical Support: Dedicated engineering support provides troubleshooting assistance, optimization guidance, and performance enhancement recommendations.

Customer Success Case Studies

Case Study 1: Automotive Tier 1 Supplier Expansion

Background: Major automotive supplier processing door panels, hood assemblies, and structural components for three OEM customers.

Challenge: Existing equipment limited to 1400mm width capacity, creating bottlenecks for new vehicle platform requirements specifying 1850mm+ coil widths.

Solution: MD-2200 installation replacing two smaller units, providing single-pass processing for all current and projected coil specifications.

Results:

- 35% throughput increase for wide-format materials

- 18% reduction in per-unit processing costs

- 22-month ROI achievement through improved efficiency

- Enhanced customer satisfaction through expanded capability

Case Study 2: Regional Steel Service Center Optimization

Background: Regional steel distributor serving construction and fabrication customers across diverse market segments.

Challenge: Growing demand for wide-format construction materials requiring processing capability beyond existing 1200mm capacity.

Solution: MD-2200 implementation enabling full-width processing for construction industry customers while maintaining precision capability for existing applications.

Results:

- 40% increase in customer base through expanded capability

- 28% revenue growth within first year

- 15% improvement in material utilization efficiency

- Competitive differentiation in regional market

Implementation Planning and Installation Requirements

Site Preparation Specifications

Foundation Requirements: Engineered foundation systems supporting 10-35 ton machine weights plus dynamic operational loads. Foundation design must accommodate thermal expansion, vibration isolation, and long-term stability requirements.

Electrical Infrastructure: Three-phase electrical service providing 422.5kW capacity with appropriate safety margins for startup loads and operational variations. Installation must comply with local electrical codes and industrial safety standards.

Facility Integration: Adequate clearance for coil handling equipment, operator access, maintenance activities, and safety compliance. Typical installation requires 12-15 meter length, 8-10 meter width, and 6-8 meter height clearance.

Operator Training and Certification

Basic Operations Training: Comprehensive 40-hour training program covering machine operation, safety procedures, quality control, and basic maintenance activities.

Advanced Operations Certification: Extended 80-hour program including troubleshooting, optimization techniques, blade configuration, and performance analysis methods.

Maintenance Training: Specialized training for maintenance personnel covering preventive maintenance, component replacement, calibration procedures, and safety protocols.

Frequently Asked Questions

What’s the maximum coil width the MD-2200 can process?

The MD-2200 processes coils up to 2150mm width, providing 500mm additional capacity compared to MD-1650’s 1650mm maximum.

Is power consumption different between MD-1650 and MD-2200?

No, both machines consume identical 422.5kW power, ensuring similar energy costs regardless of width processing capability.

Which model is better for automotive applications?

MD-2200 is typically preferred for automotive applications due to wide body panel requirements, though MD-1650 suits precision automotive components within width specifications.

How do maintenance costs compare between the models?

MD-2200 maintenance costs run approximately 12-15% higher than MD-1650 due to larger blade requirements and increased component sizes.

What safety certifications do these machines include?

Both models meet OSHA safety standards, CE certification requirements, and ISO 9001:2015 quality management standards for industrial applications.

Next Steps: Strategic Equipment Selection

Assessment Worksheet: Coil Specification Analysis

Current Material Analysis:

- Document existing coil width specifications (minimum, maximum, average)

- Identify material thickness distributions and processing volumes

- Evaluate customer requirements and specification trends

Future Growth Projection:

- Analyze projected market expansion over 5-year period

- Assess potential customer requirements and width specifications

- Consider strategic positioning and competitive advantages

Financial Analysis:

- Calculate current processing capacity limitations and costs

- Evaluate investment requirements and financing options

- Determine ROI expectations and payback objectives

Equipment Selection Decision Process

- Technical Requirements Assessment: Match current and projected coil specifications against equipment capabilities to determine minimum requirements.

- Financial Impact Analysis: Compare investment costs, operational expenses, and revenue potential for each equipment option.

- Strategic Positioning Evaluation: Consider market positioning objectives, competitive differentiation, and long-term business strategy alignment.

- Implementation Planning: Develop installation timeline, training requirements, and operational integration procedures.

Professional Consultation and Support

MaxdoMachine provides comprehensive consultation services to evaluate specific operational requirements and recommend optimal equipment configurations. Our engineering team conducts detailed facility assessments, coil specification analysis, and ROI calculations to support informed decision-making.

Get Your Custom Scaling Assessment – Compare MD-1650 vs MD-2200 for Your Specific Requirements

For detailed specifications and pricing information, visit our complete product documentation:

Conclusion: Optimizing Steel Coil Processing Investment

The selection between the MD-1650 and MD-2200 is a pivotal, long-term investment decision that shapes operational efficiency, market reach, and revenue scalability. While both models offer equivalent performance in processing thickness, speed, and energy consumption, the critical 500mm difference in maximum coil width significantly broadens the scope of application and production flexibility for the MD-2200. This expanded width capability is indispensable for industries processing large-format steel components such as automotive body panels, major appliance parts, and heavy construction materials, effectively removing constraints related to material dimensions and enabling manufacturers to capture new market segments.

Conversely, the MD-1650 provides a cost-efficient yet robust solution tailored for facilities committed to coils within 1650mm width specifications, delivering full performance parity in terms of precision, speed, and energy efficiency. This makes it ideal for specialized or medium-scale operations where capital optimization is paramount without sacrificing processing quality. Both machine platforms benefit from MaxDo’s comprehensive technical support, proven reliability, and extensive spare parts availability, ensuring seamless integration and longevity. Ultimately, the choice hinges on balancing immediate production needs with strategic growth ambitions, where the MD-2200 secures stronger future-proofing for broader market diversification, while the MD-1650 excels in targeted, high-precision applications—providing manufacturers with clearly defined paths to maximize return on investment and operational agility.

Ready to Scale Up? Our engineers provide free consultation to determine the optimal MD series configuration for your expansion plans. Contact MaxdoMachine Today for professional assessment and implementation support.