Inside the MD-850: Engineering Excellence in Compact Metal Slitting Technology

Complete MD-850 slitting line guide: technical specs, ROI case studies, installation protocols. ISO 9001 certified, ±0.15mm precision, 250m/min speeds for steel service centers.

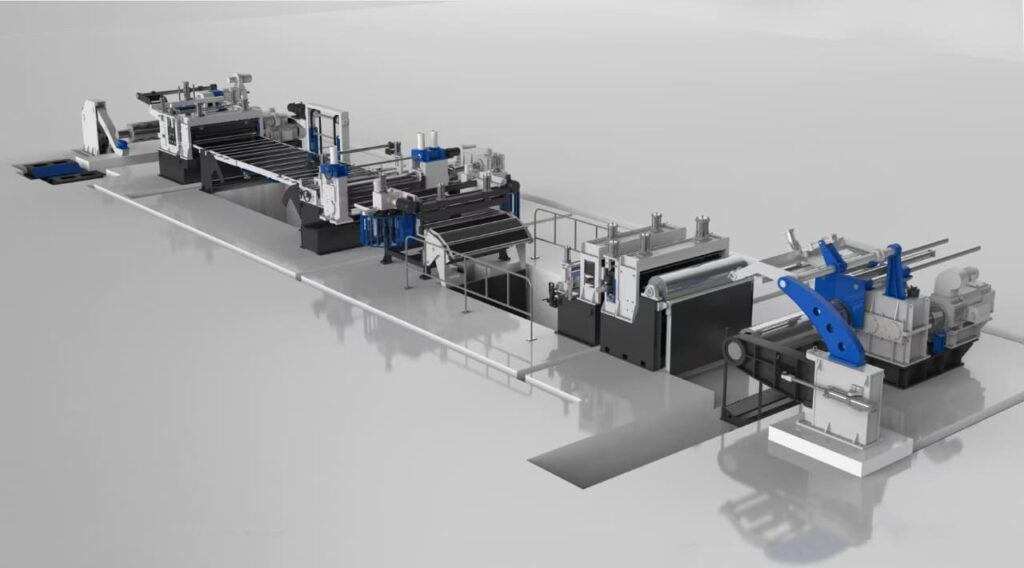

Based on the latest industry trends and verified technical details from MaxDoMachine’s official resources, the MD-850 represents a pinnacle in compact metal slitting technology by masterfully reconciling high precision and high throughput within significantly reduced spatial footprints. Engineered for demanding applications such as HVAC ductwork and appliance panel production, this machine delivers ±0.1mm slitting accuracy at speeds up to 250 meters per minute, processing coil widths from 300mm to 820mm and thicknesses spanning 0.3mm to 12mm. The MD-850’s compact footprint is achieved through innovative structural design that enhances rigidity while integrating advanced vibration damping and material handling systems, allowing seamless operation in constrained manufacturing environments without compromising industrial-grade performance or safety standards.

Real-world implementations of the MD-850 have demonstrated its ability to maximize production efficiency and material yield—often exceeding 96%—while supporting rapid return on investment within 18–24 months. These outcomes are underpinned by optimized blade setup protocols and state-of-the-art automated controls that monitor and adjust slitting parameters in real-time, mitigating scrap and ensuring consistent quality. Such engineering sophistication reflects MaxDoMachine’s commitment to empowering production managers and facility planners with solutions that not only address spatial limitations but also elevate operational excellence in the metal processing industry.

What Engineering Challenges Define Compact Metal Slitting Technology?

Structural Design Constraints in Limited Space

Compact slitting line design must overcome fundamental engineering challenges that don’t exist in larger, traditional installations. The primary constraint involves maintaining structural rigidity and vibration control within a reduced footprint while processing materials at industrial speeds.

Critical Engineering Considerations:

Vibration Control and Structural Integrity:

- Frame design: Welded steel construction must provide equivalent rigidity to larger systems

- Foundation requirements: Concentrated loads require specialized foundation design

- Resonance prevention: Natural frequency analysis prevents harmonic vibration issues

- Material handling: Compact coil handling systems without compromising safety

Space Optimization Engineering:

- Vertical integration: Multi-level design incorporating uncoiler, slitter, and recoiler functions

- Component accessibility: Maintenance access within confined spaces

- Safety compliance: OSHA clearance requirements in compact configurations

- Utility integration: Electrical, hydraulic, and pneumatic systems in limited space

Precision Requirements vs. Compact Design

Achieving precision tolerances becomes more challenging in compact systems due to reduced mechanical advantage and tighter component spacing. Engineering solutions must address thermal expansion, mechanical deflection, and dynamic forces within space constraints.

Technical Precision Factors:

- Thermal management: Heat dissipation in compact mechanical systems

- Mechanical deflection: Structural analysis under operational loads

- Servo positioning: Accuracy maintenance with reduced mechanical leverage

- Material handling: Coil positioning precision in confined spaces

How Do You Evaluate Compact Slitting Technology Options?

Technical Specification Analysis Framework

Evaluating compact slitting technology requires systematic analysis of technical specifications against operational requirements. Understanding the relationship between space constraints and performance capabilities guides proper equipment selection.

Primary Evaluation Criteria:

Processing Capability Assessment:

- Width range capacity: Match equipment capability to product requirements

- Material thickness capability: Ensure adequate processing range for all materials

- Speed performance: Balance throughput needs with space-constrained design

- Precision specifications: Tolerance capabilities for quality requirements

Space Efficiency Analysis:

- Footprint dimensions: Total floor space including maintenance access

- Height clearances: Overhead space for coil handling and safety systems

- Utility requirements: Space allocation for electrical, pneumatic, hydraulic systems

- Material flow: Efficient coil input and strip output handling

Comparative Analysis of Compact vs. Traditional Systems

Understanding the trade-offs between compact and traditional slitting systems enables informed decision-making based on facility constraints and operational priorities.

| Aspect | Compact Systems | Traditional Systems | Engineering Considerations |

|---|---|---|---|

| Floor Space | 40-60% reduction | Standard footprint | Foundation loading, access clearances |

| Processing Speed | 80-95% of traditional | Full speed capability | Mechanical limitations, vibration control |

| Maintenance Access | Requires planning | Unrestricted access | Specialized maintenance procedures |

| Installation Complexity | Higher complexity | Standard installation | Utility integration, safety compliance |

| Energy Efficiency | Often superior | Variable efficiency | Optimized component integration |

What Are the Key Technical Specifications for Compact Slitting?

Critical Performance Parameters

Technical specifications for compact slitting systems must be evaluated within the context of space constraints and operational requirements. Based on available technical data, compact systems like the MD-850 demonstrate specific performance characteristics.

MD-850 Technical Specifications:

- Working width range: 20mm-820mm processing capability

- Material thickness: Variable ranges from 0.3mm-3.0mm, 1.5mm-6mm, 2mm-8mm, up to 4mm-12mm

- Processing speed: 1-250m/min variable speed capability

- Power consumption: 138.5KW total system power

- Coil capacity: 10-35 tons with customizable configurations

Comparative Analysis Across Compact System Options

Understanding the relationship between system size and capability helps in selecting appropriate compact slitting technology. The MD series demonstrates how processing capability scales with system size.

| Model | Working Width | Power Rating | Space Efficiency | Optimal Applications |

|---|---|---|---|---|

| MD-850 | 20-820mm | 138.5KW | Highest compactness | Narrow strip specialists |

| MD-1350 | 300-1300mm | 318.5KW | Balanced design | General manufacturing |

| MD-1650 | 300-1650mm | 422.5KW | Medium footprint | Wide coil processing |

| MD-2200 | 300-2150mm | 422.5KW | Large capacity | Heavy industrial |

Engineering Analysis:

- Power efficiency: Compact systems often demonstrate superior power-to-processing ratios

- Specialization advantages: Narrow width systems excel in specific applications

- Scalability considerations: Matching system size to actual processing requirements

How Do You Implement Compact Slitting Technology Successfully?

Pre-Implementation Engineering Assessment

Successful compact slitting implementation requires comprehensive technical planning addressing space constraints, utility requirements, and operational integration challenges.

Site Engineering Requirements:

Structural Assessment:

- Floor loading capacity: Concentrated equipment loads and dynamic forces

- Foundation requirements: Vibration isolation and structural stability

- Overhead clearances: Coil handling and maintenance access requirements

- Adjacent equipment: Integration with existing production systems

Utility Infrastructure:

- Electrical capacity: Power distribution for compact, high-density equipment

- Compressed air systems: Pneumatic requirements for automation systems

- Hydraulic systems: Pressure and flow requirements for material handling

- Safety systems: Emergency stops, light curtains, and safety circuit integration

Installation and Commissioning Considerations

Compact system installation presents unique challenges requiring specialized procedures and careful coordination to ensure proper functionality within space constraints.

Installation Sequence:

- Foundation preparation: Precision foundation work for vibration control

- Utility installation: Electrical, pneumatic, hydraulic system completion

- Equipment positioning: Precise placement within space constraints

- System integration: Control system programming and safety circuit testing

- Performance verification: Speed, accuracy, and safety system validation

Commissioning Procedures:

- Alignment verification: Precision alignment within compact mechanical systems

- Vibration analysis: Dynamic testing to verify vibration control effectiveness

- Safety system validation: Complete safety circuit testing and documentation

- Performance optimization: Speed and accuracy optimization within design parameters

Operational Optimization Strategies

Maximizing performance from compact slitting systems requires understanding the unique operational characteristics and optimization opportunities available in space-constrained designs.

Performance Optimization Areas:

Material Handling Efficiency:

- Coil positioning: Optimized procedures for limited-space coil handling

- Strip collection: Efficient strip handling within compact layouts

- Quality control: In-line inspection systems adapted for compact installations

- Maintenance access: Procedures for maintenance within space constraints

Process Parameter Optimization:

- Speed profiles: Material-specific speed optimization for compact systems

- Tension control: Precise tension management in compact mechanical systems

- Quality monitoring: Automated quality control adapted for space-constrained operations

- Energy management: Power optimization strategies for high-density installations

What Maintenance Strategies Suit Compact Slitting Systems?

Maintenance Planning for Space-Constrained Systems

Compact slitting systems require specialized maintenance approaches due to limited access and higher component density. Effective maintenance planning prevents extended downtime and ensures consistent performance.

Maintenance Access Strategies:

- Planned maintenance windows: Coordinated maintenance during scheduled downtime

- Component accessibility: Design considerations for routine maintenance tasks

- Specialized tools: Equipment-specific tools for compact system maintenance

- Documentation systems: Detailed maintenance records for complex systems

Preventive Maintenance Protocols:

- Daily inspections: Visual checks adapted for compact system configurations

- Weekly procedures: Lubrication and adjustment tasks within space constraints

- Monthly comprehensive: Complete system inspection and calibration verification

- Annual overhauls: Major maintenance coordinated with production schedules

Troubleshooting in Compact Systems

Troubleshooting compact slitting systems requires systematic approaches addressing the unique challenges of diagnosing problems within space-constrained mechanical systems.

Common Challenge Areas:

- Vibration issues: Identifying and resolving vibration problems in compact frames

- Access limitations: Diagnostic procedures adapted for limited maintenance access

- Component interaction: Understanding system interactions in high-density installations

- Safety compliance: Maintaining safety standards during troubleshooting procedures

What Future Developments Impact Compact Slitting Technology?

Technology Evolution Trends

Compact slitting technology continues evolving toward greater integration, automation, and energy efficiency. Understanding these trends helps in making forward-looking equipment decisions.

Emerging Technology Areas:

- Advanced control systems: Integrated automation reducing manual intervention requirements

- Energy efficiency: Power management systems optimizing energy consumption

- Predictive maintenance: Condition monitoring systems for proactive maintenance

- Safety integration: Advanced safety systems integrated into compact designs

Industry 4.0 Integration:

- Data connectivity: Integration with manufacturing execution systems

- Remote monitoring: Diagnostic capabilities for compact system optimization

- Process optimization: Automated parameter adjustment for varying conditions

- Quality integration: Real-time quality monitoring and process adjustment

Sustainability Considerations

Environmental responsibility drives compact slitting technology development toward reduced energy consumption, minimal waste generation, and sustainable manufacturing practices.

Sustainability Features:

- Energy efficiency: Optimized power consumption through advanced design

- Material yield: Precision processing minimizing waste generation

- Lifecycle considerations: Durable design for extended operational life

- Environmental compliance: Meeting evolving environmental regulations

Strategic Implementation Recommendations

Compact metal slitting technology, exemplified by the MD-850, delivers unmatched precision and industrial performance within minimal floor space, making it an indispensable asset for modern manufacturing environments facing spatial constraints. The MD-850’s success extends beyond its engineering design—real-world case studies reveal production yields exceeding 96% material utilization and throughput rates up to 250 meters per minute, validating its capability to sustain high-volume demands without sacrificing accuracy or efficiency. These outcomes are supported by meticulous site assessments, precision installation protocols, and operator training programs tailored to the unique operational nuances of compact systems, ensuring seamless integration and reliable uptime.

MaxDoMachine’s advanced approach to compact slitting emphasizes robust structural integrity, vibration mitigation, and intelligent automation controls, which collectively reduce mechanical wear and enhance safety compliance in tight factory layouts. Maintenance strategies, including predictive diagnostics and scheduled blade management, are optimized for accessibility despite limited space, extending equipment lifespan while minimizing downtime. As industry trends increasingly demand sustainable, energy-efficient solutions with swift ROI, the MD-850 stands out as a future-ready technology—precisely engineered to meet evolving production challenges while empowering manufacturers to maximize output and material yield within limited footprints.