Maxdo Machinery Secures Breakthrough Contract for Intelligent Aluminum Alloy Slitting Line

This deal expands Maxdo's global footprint while elevating benchmarks for smart slitting in aluminum alloy production, fostering efficient, eco-friendly chains worldwide.

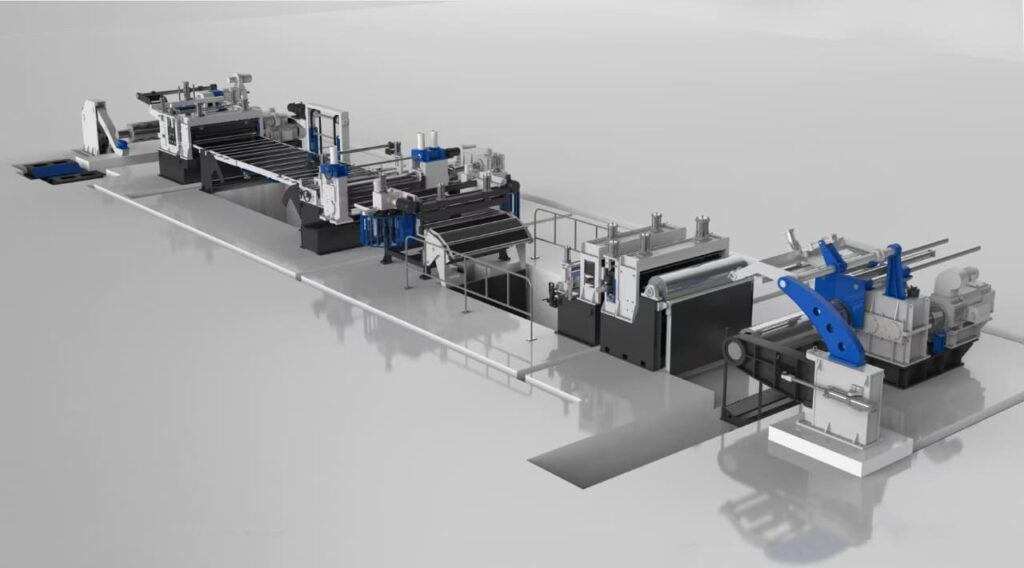

In a major milestone for global metal processing, Maxdo Machinery has secured a pivotal contract to deliver an intelligent slitting line optimized for aluminum alloy materials to a premier toll processing center in the Midwest United States. This cutting-edge system is crafted to meet the rigorous precision needs of aerospace and automotive industries, revolutionizing aluminum coil management with velocities reaching 250 meters per minute.

What Defines an Intelligent Slitting Line for Aluminum Alloy Processing?

Aluminum alloys demand precise handling to preserve surface quality and exact dimensions, particularly in slitting processes that transform broad coils into targeted strips. An intelligent slitting line stands apart by leveraging AI for instantaneous tension regulation and flaw identification, slashing scrap rates and upholding superior output standards.

This Maxdo initiative exemplifies the global pivot to automated slitting solutions, where integrated sensors oversee material progression and fine-tune blade alignment on the fly. For B2B decision-makers weighing slitting lines against cut-to-length lines, slitting operations deliver unmatched efficiency in strip manufacturing, boosting aluminum workflows by as much as 30% over legacy configurations.

Essential Specifications and Innovations in Maxdo’s Advanced Slitting Line

Drawing from Maxdo’s MD-2200MM platform, the commissioned line offers robust adaptability for aluminum alloy demands. It accommodates coil widths of 300mm to 2150mm and thicknesses from 0.3mm to 12mm, spanning delicate foils to robust panels.

- Primary Mechanism: Advanced rotary shear with intelligent servo systems, enabling over 200 cuts per minute without compromising edge sharpness.

- Smart Integrations: Vision-based inspection for defect spotting, combined with an automated cleaning module to shield pristine aluminum surfaces from impurities.

- Uncoiler and Handling: Electric uncoiler featuring regenerative braking for sustainable tension management, channeling into a dual continuous stacker for fluid material flow.

- Performance Metrics: 422.5KW total power, with speeds adjustable from 1 to 250m/min depending on alloy thickness.

Positioned as a leader in international aluminum slitting, this setup matches top-tier standards worldwide for accuracy and pace. Explore model breakdowns in our MD series catalog.

| Feature | MD-2200MM Slitting Line | Conventional Aluminum Slitter |

|---|---|---|

| Max Width | 2150mm | 1500mm |

| Thickness Range | 0.3-12mm | 0.5-8mm |

| Speed | Up to 250m/min | Up to 150m/min |

| Inspection | AI Vision System | Basic/Manual Checks |

| Energy Use | Regenerative Braking | Standard Drives |

Why Opt for Slitting Lines in Aluminum Alloy for Demanding Global Sectors?

Aluminum’s low density suits it perfectly for electric vehicles and aviation, yet its malleability calls for slitting lines equipped with scratch-resistant guides and meticulous edge control to eliminate imperfections. This Maxdo agreement tackles these issues directly, with optional PVC applicators for in-line protective layering.

Experts highlight that suboptimal slitting can cause 15-20% yield losses in aluminum; smart platforms like this drop it below 5% via data-driven forecasting. Gain insights into core slitting principles from the North American Metalworking Association or metal slitting techniques on Wikipedia.

When comparing slitting to cut-to-length lines or flatbed sheeters, slitting proves superior for streamlined strip output, yielding ready components sans extra cuts.

Project Timeline and Boost to International Aluminum Efficiency

Set for shipment in early 2026, the line will be installed and operational by mid-year, empowering the U.S.-based partner to expand in aluminum-driven markets. This collaboration reinforces Maxdo’s focus on overseas innovation and reliable coil automation expertise.

Overseas clients can anticipate strong returns, with predictive upkeep reducing outages by 40%. Witness comparable tech at work in our certificate or reach out for a tailored international consultation.