Choosing Between Slitting and CTL for Aluminum, Stainless, and Mild Steel Coils

Slitting lines excel in converting wide coils into multiple narrow strips while maintaining coil form, making them ideal for tube manufacturing, roll forming, and component production.

Production managers navigating the complexities of modern metal coil processing face a pivotal equipment selection that critically shapes operational efficiency and material optimization: deciding between advanced slitting lines and cut-to-length (CTL) lines for aluminum, stainless steel, and mild steel coils. Each technology serves distinct manufacturing profiles—slitting excels in precision strip widths with superior edge quality essential for continuous fabrication in electronics, automotive, and construction sectors, while CTL lines deliver high-volume, accurately length-cut flat sheets indispensable for heavy-gauge steel applications such as structural panels and industrial components.

Investing in the right coil processing equipment directly influences material yield, throughput, and long-term cost efficiency, with improper choice triggering operational expenses rising by up to 30%, alongside reduced product quality and market competitiveness. Real-world implementations confirm that modern slitting lines equipped with automated blade gap controls and servo-driven tension management achieve up to 20% less scrap in aluminum thin gauges, preserving surface integrity and minimizing work hardening. Meanwhile, CTL lines leverage precision leveling and tandem shearing technology to ensure tight length tolerances and flatness for stainless and mild steel sheets exceeding 12mm thickness, supported by automation that reduces manual interventions and accelerates production cycles.

At MaxDoMachine, integrating cutting-edge automation with proven mechanical robustness ensures optimized coil processing tailored to specific alloy properties and end-use demands. This guide provides an expert framework, grounded in technical rigor and industry case studies, to empower decision-makers to maximize return on investment while aligning operational goals with evolving market requirements.

Understanding Core Processing Requirements: Slitting vs CTL Analysis

When Slitting Lines Deliver Superior ROI

Slitting operations excel when your production profile aligns with specific operational characteristics. These systems convert wide master coils into multiple narrow strips through precision longitudinal cutting while maintaining coil form—essential for downstream processing efficiency.

Slitting lines provide optimal value when:

- Strip production dominates: 60% or more of your output requires narrow to medium-width strips

- Multiple outputs needed: Single coil setups producing 3-8 strips maximize throughput efficiency

- Coil form advantages: Downstream operations benefit from continuous material feed

- Variable width flexibility: Customer specifications require frequent width changes

For detailed technical specifications on how modern slitting systems achieve these advantages, explore our advanced metal slitting lines guide.

Key performance indicators favoring slitting:

- Strip widths ranging from 20mm to 2,150mm (depending on equipment capacity)

- Material utilization rates exceeding 95% with proper setup

- Processing speeds up to 250m/min for optimal materials

- Changeover times reduced to 15-30 minutes with experienced operators

CTL Line Optimization for Flat Sheet Production

Cut-to-length lines shine when flat sheet production represents your primary operational focus. These systems uncoil material, eliminate coil set through precision leveling, and produce dimensionally accurate flat sheets ready for fabrication processes.

CTL lines deliver superior performance when:

- Flat sheet requirements exceed 70% of production volume

- Dimensional accuracy is critical: Tolerances within ±0.15mm required

- Fabrication integration planned: Direct feeding to stamping, welding, or assembly operations

- Standard dimensions dominate: Consistent sheet sizes enable efficient processing

For a comprehensive comparison of both technologies, review our detailed analysis of metal slitting vs CTL lines.

Material-Specific Processing Analysis

Aluminum Coil Processing Considerations

Aluminum’s unique characteristics significantly influence equipment selection decisions. Work-hardening properties and lower tensile strength require specialized processing approaches to prevent edge cracking and maintain surface finish quality.

Critical aluminum processing factors:

- Tension control: Lower settings prevent material stretching and edge defects

- Blade selection: Specialized geometries optimize cut quality for aluminum alloys

- Surface protection: Coated rollers prevent scratching during processing

- Temperature management: Heat buildup affects dimensional stability

Processing recommendations:

- Slitting speeds: 80-150m/min for optimal edge quality

- CTL processing: Enhanced leveling reduces aluminum’s tendency toward coil set

- Blade life: 2-3x longer replacement intervals compared to steel processing

Stainless Steel Processing Requirements

Stainless steel processing demands robust equipment capabilities due to higher tensile strength and increased work-hardening rates. Material resistance to deformation requires precise control systems and enhanced cutting capabilities.

Stainless steel optimization strategies:

- Enhanced cutting systems: Higher tonnage shears handle increased material strength

- Precision tension control: Multi-zone systems prevent material distortion

- Advanced blade materials: Carbide or ceramic options extend tool life

- Quality monitoring: Real-time edge inspection systems prevent defect propagation

For specific guidance on optimizing stainless steel processing, see our metal slitting vs blanking optimization guide.

Mild Steel Processing Advantages

Mild steel applications offer maximum processing flexibility with predictable forming characteristics suitable for both slitting and CTL operations. Consistent material properties enable higher processing speeds and extended tool life.

Technical Process Comparison: Equipment Capabilities

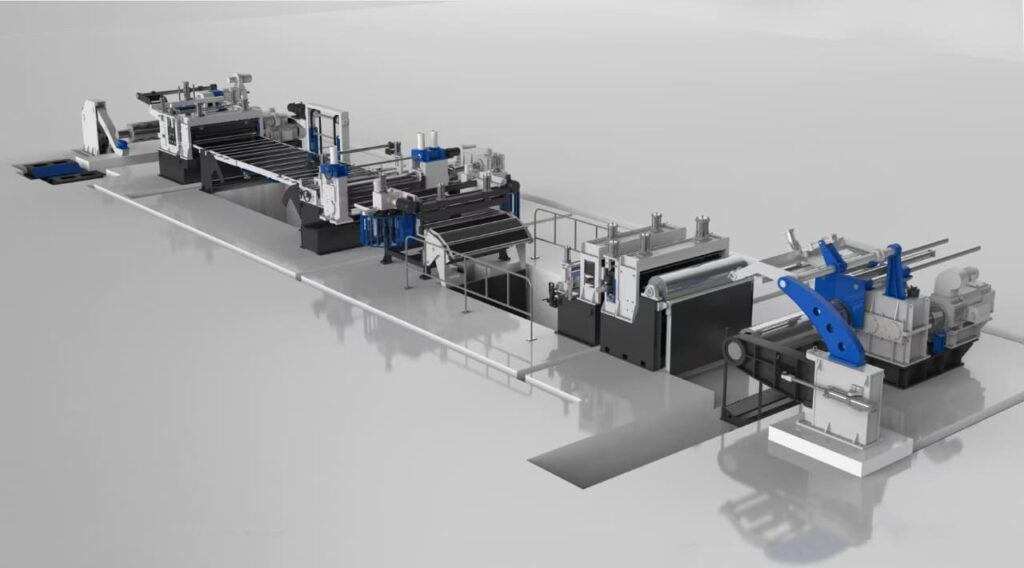

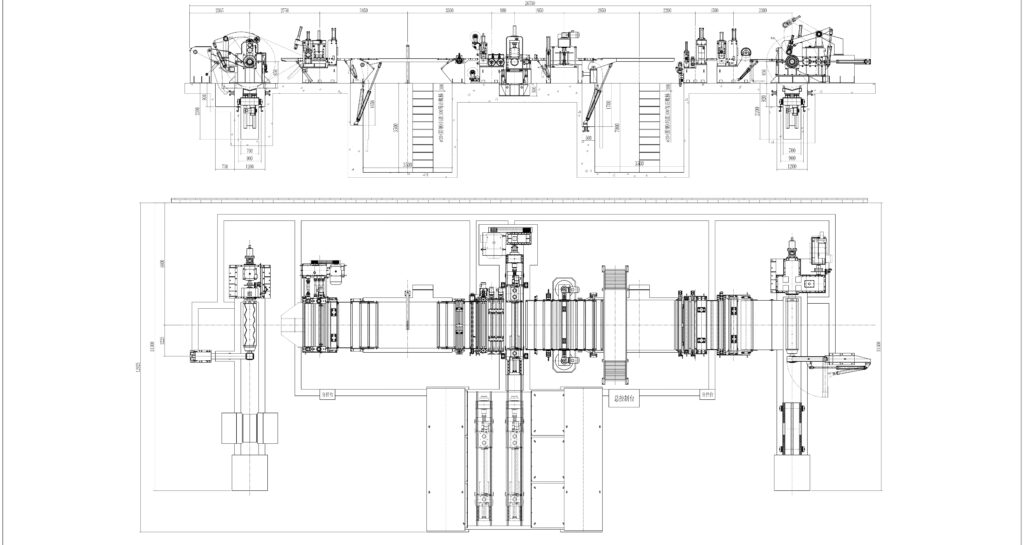

Advanced Slitting Line Technology

Modern slitting lines utilize servo-controlled rotary knife systems with precision clearance control for consistent strip quality across multiple outputs. Integration of advanced automation systems reduces setup complexity while improving consistency.

MD-Series Equipment Specifications:

MD-850 Compact Slitting Line

The MD-850 slitting machine offers specific advantages for thin-gauge material processing:

- Working width: 20mm-820mm capacity

- Thickness range: 0.3mm-12mm processing capability

- Processing speed: Up to 250m/min

- Total power: 138.5KW for efficient operation

- Applications: Ideal for HVAC ducting and appliance panels

For detailed blade setup procedures, consult our complete blade setup guide for the MD-850.

MD-1350 Mid-Range Workhorse

- Working width: 300mm-1,350mm

- Total power: 318.5KW

- Versatility: Balanced performance for diverse applications

MD-1650/2200 Heavy-Duty Systems

- MD-1650: 300mm-1,650mm width, 422.5KW power

- MD-2200: 300mm-2,150mm width, 422.5KW power

- Applications: Wide coil processing for heavy-duty operations

Get comprehensive technical insights in our inside the MD-850 engineering guide.

Cut-to-Length Line Architecture

CTL systems integrate precision leveling technology with automated shearing mechanisms to produce dimensionally accurate flat sheets. Advanced servo-shear systems achieve length tolerances within ±0.15mm consistently.

System capabilities:

- CT-850: 820mm maximum width, 93kW power consumption

- CT-1350: Mid-range capacity with enhanced precision control

- CT-1650: High-capacity processing for industrial applications

ROI Analysis and Investment Considerations

Comprehensive Cost Analysis

For detailed ROI calculations and lifecycle cost comparisons, review our slitting vs CTL lines 10-year lifecycle cost guide. This analysis includes:

Investment ranges (approximate):

- Slitting lines: $150,000-$800,000 depending on capacity

- CTL lines: $200,000-$1,200,000 based on precision requirements

- Combination systems: $400,000-$1,500,000 for integrated capabilities

Operational Cost Analysis

Long-term operational expenses often exceed initial capital investment over equipment lifecycles:

- Energy consumption: Slitting typically 15-25% lower than CTL

- Maintenance costs: CTL systems require 20-30% higher maintenance

- Material utilization: 95-98% achievable with slitting, 92-96% with CTL

Decision Framework for Optimal Equipment Selection

Application-Specific Selection Guidelines

Industry-specific recommendations:

Automotive industry:

- Choose slitting for: Tube manufacturing, roll-formed components

- Choose CTL for: Stamping applications, body panels

Construction applications:

- Choose slitting for: Roofing strips, structural components

- Choose CTL for: Architectural panels, fabrication feeding

Appliance manufacturing:

- Choose slitting for: Component strips, continuous forming

- Choose CTL for: Cabinet panels, precision parts

Quality Control and Performance Optimization

Slitting Operation Excellence

Consistent strip quality requires attention to knife selection, clearance optimization, and tension control. Advanced monitoring systems enable real-time adjustments preventing defect propagation.

Quality optimization strategies:

- Entry/exit loop systems: Controlled low-tension processing

- Automated knife positioning: Improved setup consistency

- Real-time monitoring: Immediate process adjustments

- Preventive maintenance: Scheduled blade replacement protocols

CTL Precision Control

Dimensional accuracy achievement through integrated leveling and measurement systems ensures fabrication-ready flat sheets meeting specified tolerances consistently.

MaxdoMachine Solutions and Technical Support

MaxdoMachine’s 20+ years of metal processing expertise provides comprehensive solutions optimized for aluminum, stainless steel, and mild steel applications. Learn more about our company heritage and capabilities on our about us page.

Technical advantages:

- Proven R&D excellence: Advanced solutions backed by extensive experience

- Global support network: Local technical support worldwide

- End-to-End factory solutions: Complete project management

- Quality certifications: View our official certifications and quality standards

Comprehensive Support Services

Available services:

- Technical consultation: Application engineering support

- Factory tours: Experience our manufacturing capabilities through our virtual factory tour

- FAQ support: Common questions answered in our comprehensive FAQ section

- Training programs: Operator and maintenance education

Making Your Optimal Choice

Quick Decision Matrix

Choose slitting lines when:

- ✅ Strip production represents 60%+ of volume

- ✅ Multiple narrow outputs from single setups required

- ✅ Coil form benefits downstream operations

- ✅ Variable width flexibility needed

- ✅ Material utilization efficiency critical

Choose CTL lines when:

- ✅ Flat sheet production exceeds 70% of requirements

- ✅ Dimensional accuracy within ±0.15mm critical

- ✅ Integration with automated fabrication systems planned

- ✅ Standard sheet dimensions dominate production

- ✅ Leveling requirements eliminate coil set issues

Professional Consultation Services

MaxDoMachine’s engineering experts deliver in-depth, data-driven consultations that tailor equipment solutions precisely to your operational scale, alloy specifics, and production targets. Leveraging advanced analytics and real-world performance metrics from recent deployments—such as our MD Series slitting machines reducing aluminum scrap by 18% in high-speed applications, or CTL lines enhancing mild steel sheet flatness within ±0.2mm tolerance—our team ensures equipment choices directly translate into measurable gains in efficiency, yield, and profitability.

For detailed specifications and custom configurations aligned with your unique aluminum, stainless steel, and mild steel coil processing needs, engage with our seasoned professionals. Their expertise extends beyond standard solutions to include adaptive automation integration and maintenance optimization, providing every customer with a robust, future-proof investment that maximizes throughput and return on investment while minimizing downtime and operational expenses.

This commitment to precision and performance underscores MaxDoMachine’s leadership in cutting-edge coil processing technology for 2025 and beyond.

Ready to optimize your metal processing operations? Contact MaxdoMachine today for a comprehensive analysis of your specific requirements and customized equipment recommendations.